Triple Dome Survival Shelter « Earthbag House Plans. April 12, 2011 by Owen Geiger Triple Dome Survival Shelter (click to enlarge) Specifications: Three 16′ interior diameter domes with 603 sq. ft. interior, 3 sleeping lofts with 312 sq. ft., total 915 sq. ft. interior, one bedroom, one bath, Footprint: 38′ x 38′ Description: This Triple Dome Survival Shelter provides much more space than my first earthbag survival shelter.

This design is for long term survival for a family. It is earthquake and fire resistant, bullet and nuclear fallout resistant. Like this: Like Loading... Superadobe & Earthbags - What Is Superadobe? Superadobe (sandbag and barbed wire) technology is a large, long adobe.

It is a simple adobe, an instant and flexible line generator. It uses the materials of war for peaceful ends, integrating traditional earth architecture with contemporary global safety requirements. Long or short sandbags are filled with on-site earth and arranged in layers or long coils (compression) with strands of barbed wire placed between them to act as both mortar and reinforcement (tension). Stabilizers such as cement, lime, or asphalt emulsion may be added. This patented and trademarked (U.S. patent #5,934,027, #3,195,445) technology is offered free to the needy of the world, and licensed for commercial use.

This concept was originally presented by architect Nader Khalili to NASA for building habitats on the moon and Mars, as “Velcro-adobe”. Cal-Earth believes that the whole family should be able to build together, men and women, from grandma to the youngest child. The History Of Earthbag Building. A Short History of Earthbag Building by Kelly Hart The idea of making walls by stacking bags of sand or earth has been around for at least a century.

Originally sand bags were used for flood control and military bunkers because they are easy to transport to where they need to be used, fast to assemble, inexpensive, and effective at their task of warding off both water and bullets. At first natural materials such as burlap were used to manufacture the bags; more recently woven polypropylene has become the preferred material because of its superior strength. The burlap will actually last a bit longer if subjected to sunlight, but it will eventually rot if left damp, whereas polypropylene is unaffected by moisture. Because of this history of military and flood control, the use of sandbags has generally been associated with the construction of temporary structures or barriers. 1978, a prototype house using an earthquake-proof stacked-bag type of construction was built in Guatemala.

Soil Tests For Earthbag Building (PDF) The Mud - Earthbag Building. Earthbag Construction. EarthBag Homes - you're standing on the building materials... earthbag home Long sandbags are filled on-site and arranged in layers or as compressed coils.

Stabilizers such as cement, lime, or sodium carbonate may be added to an ideal mix of 70% sand, 30% clay. Straw may also be added. The earthbags are then plastered over with adobe. Arquitectura en Equilibrio (Architecture in Balance) flickr.com earthbag home Plastic bags recycled into plastic bags -- if plastic does not break down for a thousand years, this building is sure to last several lifetimes.

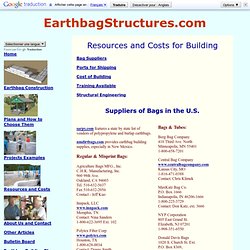

Resources for Earthbag Building. Suppliers of Bags Globally China Forest Packaging Group Co.

,Ltd www.forestpackaging.com Tel: +86 151 656 64026 Fax:+86 536 827 3455 Bill Chen, Sales Manager chinaforestpackATgmail.com Bill Chen does communicate in English. This factory in China (and Cambodia) can provide a wide range of polypropylene bags, both as individually sewn bags, and as long tubes on a rolls. They ship via containers (or partial containers) and have delivery to Haiti. Standard 18"X30" bags run about $0.11US each and the longer 18"X34" bags are about $0.12 each. The long tubing in rolls are 3500 meters (11,150' or 2.2 miles) long. They can supply gussetted bags by special order, and it would be necessary to give them exact specifications for this.

They need up to 30 days lead time to fill orders. Resources for Earthbag Building.