An ORDbot Quantum 3D printer. 3D printing or additive manufacturing[1] is a process of making a three-dimensional solid object of virtually any shape from a digital model. 3D printing is achieved using an additive process, where successive layers of material are laid down in different shapes.[2] 3D printing is also considered distinct from traditional machining techniques, which mostly rely on the removal of material by methods such as cutting or drilling (subtractive processes). A 3D printer is a limited type of industrial robot that is capable of carrying out an additive process under computer control. The 3D printing technology is used for both prototyping and distributed manufacturing with applications in architecture, construction (AEC), industrial design, automotive, aerospace, military, engineering, dental and medical industries, biotech (human tissue replacement), fashion, footwear, jewelry, eyewear, education, geographic information systems, food, and many other fields.

3D printing

High-precision 3D printers for lost wax investment casting and mold making | Solidscape

Interactive Fabrication » Fabricate Yourself

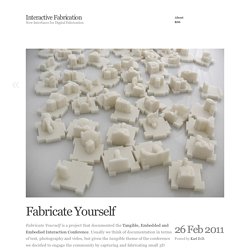

Fabricate Yourself is a project that documented the Tangible, Embedded and Embodied Interaction Conference. Usually we think of documentation in terms of text, photography and video, but given the tangible theme of the conference we decided to engage the community by capturing and fabricating small 3D models of attendees. This enabled us to build a tangible model of the event and fabricate it piece by piece during the conference. Attendees firstly capture their favorite pose using a Microsoft Kinect. The depth image from the Kinect is processed into a mesh and displayed onscreen in real-time. At any time they can capture the mesh and save it as an STL file. Dovetail joints are automatically added to the side of the models so they can be snapped together. The STL files were printed using a Dimension uPrint 3D printer kindly provided by Stratasys. Below you can see the models packed on to the 3D printing base. For those interested, a render of a full resolution model is shown below.

3D printing

3D Printers and Rapid Prototyping | Z Corporation

Bring Performance Prototyping In-House The Dimension 1200es features the largest build envelope of any Stratasys Design Series performance 3D printer. Running on Fused Deposition Modeling (FDM) Technology, it prints in nine colors of real ABSplus thermoplastic. This 3D printer lets you choose fine resolution or faster printing, with layer thicknesses of 0.254 mm (0.010 in.) or 0.33 mm (0.013 in.). Image Gallery Dimension 1200es 3D Print Pack The 3D Print Pack is everything you need to start building 3D models. The SST 1200es 3D Printer The SCA-1200 support removal system A startup supply of materials Materials and Bases Dimension 3D printers use ABSplus thermoplastic to build your models. Modeling bases provide a stable platform where your prototype builds. More Design Series Performance 3D Printers Dimension 1200es Printer Specs Model material: ABSplus in nine colors Support material: Soluble (SST 1200es); breakaway (BST 1200es) Build size: 254 x 254 x 305 mm (10 x 10 x 12 in.) BST 1200es

3D Printers, FDM Prototyping, 3D Models | Dimension Printers

MakerBot Industries

Steps to Success Every now and then we’re reminded 3D printing is not science fiction, but a real technology used every day to make amazing things in homes, studios, schools, and businesses. At MakerBot we’re proud to be leading this Next Industrial Revolution with the MakerBot 3D Ecosystem, which makes desktop 3D printing and 3D scanning affordable and reliable for everyone, and includes a variety of products and services to help unleash your creativity. One of the newest members of our family is MakerBot Desktop, a complete, free 3D printing solution for discovering, managing, and sharing your 3D prints. As we learned in last week’s post on connectivity, MakerBot Desktop was built to access the powerful software capabilities of the new Fifth Generation line of MakerBot Replicator Desktop 3D Printers. This week, we’ll take a look at how to use it to go, in just three simple steps, from a 3D design to a 3D print. 1. – Did you design your own model? – Want to browse through free designs?

Printrbot: The Perfect Beginner 3D Printer Can Expand Itself

There are a host of 3D printers out there, but none are as simple and inexpensive as the Printrbot created by Brook Drumm. It’s still in Kickstarter mode, but as of this writing,( the Printbot has already met the pledge goal. So we’re going to be seeing some of these in the future, and I know I already want to get my hands on one. There are a lot of different Printrbot kits you can order right now by pledging funds to the project: Some kits have only the basic parts, and no electronics, while some are even sparser, not even containing motors and hardware. I suppose if you got a bunch of hardware lying around and want to buy the electronics yourself that’s a good way to go, but Brook will offer a kit for $499 that includes everything you'll need to build it. The coolest part about the Printrbot is that, once you get it built, you can use it to make expansions to the bot. What’s the first thing you would print with one of these? [Kickstarter] Like this?

DIY High Resolution 3D Printer

Even though 3D printers have become mainstream and costs have declined, most cannot create a fine level of detail when printing. For rapid prototyping, you can fabricate one yourself such as the High Resolution DLP 3D Printer. Homemade yet still turns out impressive results. The 3D printer uses a Digital Light Processing chip with a high resolution video projector to render each layer of the image on a resin which is cured by a UV laser layer by layer. Popular 3D Printer Projects:

Even though 3D printers have become mainstream and costs have declined, most cannot create a fine level of detail when printing. For rapid prototyping, you can fabricate one yourself such as the High Resolution DLP 3D Printer. Homemade yet still turns out impressive results. The 3D printer uses a Digital Light Processing chip with a high resolution video projector to render each layer of the image on a resin which is cured by a UV laser layer by layer. Popular 3D Printer Projects:

3D printing

HP Designjet 3D Printer Now On Sale, Churns Out Solid Plastic Objects From the Desktop

Remember back in January when HP announced it would bring a tabletop 3-D printer to market, at a place and time to be named later? That place and time just became a quite a bit less ambiguous. Today Stratasys, the company that is manufacturing the device for HP, announced that it has shipped the first units of the HP-branded Designjet 3D fabrication machines, which will be available in May -- but only in Europe. The Designjet 3D is based on Stratasys's Fused Deposition Modeling (FDM) technology, which turns three-dimensional CAD drawings into tangible prototypes by extruding partially molten ABS plastic in extremely fine layers one atop the other, forming the entire 3-D model in a single piece from the ground up. Aimed at businesses large and small as well as educational institutions and individual inventors, the idea is to offer a point of entry into 3-D printing for those who want to prototype in-house directly from their computers. [HP, Stratasys]

Chipotle Beware: BurritoBot Will 3D Print Your Lunch to Order

Marko Manriquez has two passions: digital fabrication and good food. Fulfilling both of these passions is his master’s thesis at the Tisch School of the Arts. It’s called the BurritoBot, and it 3D prints burritos. Using an iPhone app to build your order, the BurritoBot will receive the data and start making your burrito. We don’t know when the BurritoBot will be ready for commercial prime time, but you can follow Manriquez’s project on his burritob0t website. Below is a video from Mashable that showcases the BurritoBot.

Making 3D Printing Accessible: Interview with Tinkercad Founder

Kai Backman, co-founder and CEO of Helsinki-based Tinkercad, was interviewed by Wired magazine last week. Tinkercad allows mainstream consumers to design 3D models in their web browser for free, competing with traditional professional software costing thousands of dollars. Below are some excerpts from the interview. What inspired you to create Tinkercad? Tinkercad was born from a very personal frustration. In 2009, I started researching the new emerging 3-D printing technology and eventually bought my first printer by the end of the year. On the Tinkercad Comunity We let users choose how they want to publish their things and a lot of them use a Creative Commons license. Asked what Kai’s favorite 3D design is in the community, he pointed us to an historic train station on the Harlem line called Brewster Station. Below is a video walkthrough of Tinkercad that showcases how it is feature rich despite the fact that it runs in a browser. Read the full interview at Wired.

The biggest question in my head for years has been this. Can you start a business with a desktop 3D printer? With a nice little Makerbot, or a RepRap and a really useful product design, can I actually be my own, cigar-sucking factory boss? In my own living room, with a bathrobe on? An intriguing thought, but do the numbers support such a possibility? As evidence show: YES! They decided to test the hypothesis of whether or not an entrepreneur can bootstrap their business by buying a cheap 3D printer and selling their one design. The part costs was a mere $13.40, roughly 60% of the full $19.95 price tag. Between December 2010 and September 2011, 42 orders of 51 Trik Adapters were printed by their Makerbot, plus 56 that were outsourced. Their conclusion was pretty simple. For the entrepreneur, 3D printing is a massive boon because the value of a product can be tested on the open market and quickly brought back to the original designer. All in all, kickass.

The biggest question in my head for years has been this. Can you start a business with a desktop 3D printer? With a nice little Makerbot, or a RepRap and a really useful product design, can I actually be my own, cigar-sucking factory boss? In my own living room, with a bathrobe on? An intriguing thought, but do the numbers support such a possibility? As evidence show: YES! They decided to test the hypothesis of whether or not an entrepreneur can bootstrap their business by buying a cheap 3D printer and selling their one design. The part costs was a mere $13.40, roughly 60% of the full $19.95 price tag. Between December 2010 and September 2011, 42 orders of 51 Trik Adapters were printed by their Makerbot, plus 56 that were outsourced. Their conclusion was pretty simple. For the entrepreneur, 3D printing is a massive boon because the value of a product can be tested on the open market and quickly brought back to the original designer. All in all, kickass.

Bootstrapping a 3D Printed Design is Profitable

This article was submitted by a one of our readers. New technology often arrives hand-in-hand with ethical or legal quandaries. When agribusinesses first began to patent new cultivars of drought-resistant or higher-yield crops, farmers wondered how a company could patent a living thing. When bioengineers first began transferring genes from those new plant cultivars to other crops in order to produce frost-resistant fruits or vegetables that were immune from specific diseases, people debated whether or not genetic modification was ethical. 3D Scanners Open Door to Intellectual Property Infringement The cutting-edge of manufacturing technology is now 3D printing. The coupling of 3D digital modeling with 3D printing technology places an unprecedented ability into the hands of any consumer-–or competitor. Additive manufacturing, which is commonly called 3D printing, is a method of manufacturing that builds a product layer upon layer, very thin layers of material. Enter 3D Printing Related

3D Printing And Intellectual Property Rights Issues

By J.C. Lundberg, Blog Editor On March 28th, Stuart P. Green ran an op-ed in the New York Times arguing that sometimes “stealing isn’t stealing.” Several blogs, including Gigaom, picked up the story but the argument has not yet been analyzed in light of the growing developments in the area of 3D printing. This issue is not (entirely) idle speculation, however; in January of 2011, a user uploaded files on Thingverse that allows someone to print the pieces required to play Settlers of Catan. The problem in this case, however, is that while copyright law certainly protects Star Trek, it does not meaningfully protect Settlers of Catan. Like this: Like Loading...

Piracy, “Theft” and 3D Printing « Law, Technology & Arts Blog

Clone_Wars_3D_Printing

Cambridge University Engineering Department - Qi Pan

ProFORMA: Probabilistic Feature-based On-line Rapid Model Acquisition [Home] [2009 BMVC Paper (6.3MB)] [BibTeX] Off-line model reconstruction relies on an image collection phase and a slow reconstruction phase, requiring a long time to verify a model obtained from an image sequence is acceptable. We propose a new model acquisition system, called ProFORMA, which generates a 3D model on-line as the input sequence is being collected. As the user rotates the object in front of a stationary camera, a partial model is reconstructed and displayed to the user to assist view planning. The model is also used by the system to robustly track the pose of the object. Models are rapidly produced through a Delaunay tetrahedralisation of points obtained from on-line structure from motion estimation, followed by a probabilistic tetrahedron carving step to obtain a textured surface mesh of the object. Figure 1: Left to right (a) Object rotated by hand in front of camera. Acknowledgements

Solar Sinter 2011 In August 2010 I took my first solar machine - the Sun-Cutter - to the Egyptian desert in a suitcase. This was a solar-powered, semi-automated low-tech laser cutter, that used the power of the sun to drive it and directly harnessed its rays through a glass ball lens to ‘laser’ cut 2D components using a cam-guided system. The Sun-Cutter produced components in thin plywood with an aesthetic quality that was a curious hybrid of machine-made and “nature craft” due to the crudeness of its mechanism and cutting beam optics, alongside variations in solar intensity due to weather fluctuations. In the deserts of the world two elements dominate - sun and sand. My first manually-operated solar-sintering machine was tested in February 2011 in the Moroccan desert with encouraging results that led to the development of the current larger and fully-automated computer driven version - the Solar-Sinter.

SolarSinter : markus kayser

3D Printing Technology Poised for New Industrial Revolution

When the TV series Star Trek first brought the starship Enterprise into German living rooms, the concept of a replicator was pure science fiction, a fantastical utopian vision we might experience one day centuries in the future. Replicators, something of a mixture between computer and miniature factory, were capable of creating food and replacement parts from next to nothing. They were highly practical devices, since Captain Kirk couldn't exactly take along a lot of supplies for his journeys through outer space. That futuristic vision, though, has receded far into the past -- overtaken by the present. The real-world replicator-like technology poised to revolutionize the world is known as 3-D printing, though that term is misleading, since the process has little to do with printing. Three-dimensional printers can be as small as a suitcase or as large as a telephone booth, depending on the object they are meant to faithfully replicate from a 3-D computer blueprint. A Slow Process

Microsoft Releases 3D Builder App for Windows 8.1 — A Building Base for Easy 3D Printing

10 Reasons to be Bullish About the 3D Printing Industry

The Best Free 3D Program Ever? ShapeShifter

Behokh Khoshnevis Wants To 3D Print Your Next House

Lab-grown functioning kidney successfully transplanted in rats

3D printing may put global supply chains out of business: report

Printing Prospects: 10 Hi-Tech Printer Prototypes & Concepts

RoBo 3D Printer by RoBo 3D Printer

10 Ways 3D Printing Can Be Used In Education... |

3D Printing Umbilical Cord Clamps in Haiti

African Jumpstart With 3D Printing? - Fabbaloo -

3D Printing Month

Why Does 3D Printing Matter?

Express Yourself in 3D

Welcome To 3DS Central

Fabbaloo

Automated Spherical Panorama tripod for DSLR

3D printing

3D printing

Printrbot: The Perfect Beginner 3D Printer Can Expand Itself

There are a host of 3D printers out there, but none are as simple and inexpensive as the Printrbot created by Brook Drumm. It’s still in Kickstarter mode, but as of this writing,( the Printbot has already met the pledge goal. So we’re going to be seeing some of these in the future, and I know I already want to get my hands on one. There are a lot of different Printrbot kits you can order right now by pledging funds to the project: Some kits have only the basic parts, and no electronics, while some are even sparser, not even containing motors and hardware. I suppose if you got a bunch of hardware lying around and want to buy the electronics yourself that’s a good way to go, but Brook will offer a kit for $499 that includes everything you'll need to build it. The coolest part about the Printrbot is that, once you get it built, you can use it to make expansions to the bot. What’s the first thing you would print with one of these? [Kickstarter] Like this?

Printrbot: The Perfect Beginner 3D Printer Can Expand Itself

There are a host of 3D printers out there, but none are as simple and inexpensive as the Printrbot created by Brook Drumm. It’s still in Kickstarter mode, but as of this writing,( the Printbot has already met the pledge goal. So we’re going to be seeing some of these in the future, and I know I already want to get my hands on one. There are a lot of different Printrbot kits you can order right now by pledging funds to the project: Some kits have only the basic parts, and no electronics, while some are even sparser, not even containing motors and hardware. I suppose if you got a bunch of hardware lying around and want to buy the electronics yourself that’s a good way to go, but Brook will offer a kit for $499 that includes everything you'll need to build it. The coolest part about the Printrbot is that, once you get it built, you can use it to make expansions to the bot. What’s the first thing you would print with one of these? [Kickstarter] Like this?

Even though 3D printers have become mainstream and costs have declined, most cannot create a fine level of detail when printing. For rapid prototyping, you can fabricate one yourself such as the High Resolution DLP 3D Printer. Homemade yet still turns out impressive results. The 3D printer uses a Digital Light Processing chip with a high resolution video projector to render each layer of the image on a resin which is cured by a UV laser layer by layer. Popular 3D Printer Projects:

Even though 3D printers have become mainstream and costs have declined, most cannot create a fine level of detail when printing. For rapid prototyping, you can fabricate one yourself such as the High Resolution DLP 3D Printer. Homemade yet still turns out impressive results. The 3D printer uses a Digital Light Processing chip with a high resolution video projector to render each layer of the image on a resin which is cured by a UV laser layer by layer. Popular 3D Printer Projects:

HP Designjet 3D Printer Now On Sale, Churns Out Solid Plastic Objects From the Desktop

Remember back in January when HP announced it would bring a tabletop 3-D printer to market, at a place and time to be named later? That place and time just became a quite a bit less ambiguous. Today Stratasys, the company that is manufacturing the device for HP, announced that it has shipped the first units of the HP-branded Designjet 3D fabrication machines, which will be available in May -- but only in Europe. The Designjet 3D is based on Stratasys's Fused Deposition Modeling (FDM) technology, which turns three-dimensional CAD drawings into tangible prototypes by extruding partially molten ABS plastic in extremely fine layers one atop the other, forming the entire 3-D model in a single piece from the ground up. Aimed at businesses large and small as well as educational institutions and individual inventors, the idea is to offer a point of entry into 3-D printing for those who want to prototype in-house directly from their computers. [HP, Stratasys]

HP Designjet 3D Printer Now On Sale, Churns Out Solid Plastic Objects From the Desktop

Remember back in January when HP announced it would bring a tabletop 3-D printer to market, at a place and time to be named later? That place and time just became a quite a bit less ambiguous. Today Stratasys, the company that is manufacturing the device for HP, announced that it has shipped the first units of the HP-branded Designjet 3D fabrication machines, which will be available in May -- but only in Europe. The Designjet 3D is based on Stratasys's Fused Deposition Modeling (FDM) technology, which turns three-dimensional CAD drawings into tangible prototypes by extruding partially molten ABS plastic in extremely fine layers one atop the other, forming the entire 3-D model in a single piece from the ground up. Aimed at businesses large and small as well as educational institutions and individual inventors, the idea is to offer a point of entry into 3-D printing for those who want to prototype in-house directly from their computers. [HP, Stratasys]

The biggest question in my head for years has been this. Can you start a business with a desktop 3D printer? With a nice little Makerbot, or a RepRap and a really useful product design, can I actually be my own, cigar-sucking factory boss? In my own living room, with a bathrobe on? An intriguing thought, but do the numbers support such a possibility? As evidence show: YES! They decided to test the hypothesis of whether or not an entrepreneur can bootstrap their business by buying a cheap 3D printer and selling their one design. The part costs was a mere $13.40, roughly 60% of the full $19.95 price tag. Between December 2010 and September 2011, 42 orders of 51 Trik Adapters were printed by their Makerbot, plus 56 that were outsourced. Their conclusion was pretty simple. For the entrepreneur, 3D printing is a massive boon because the value of a product can be tested on the open market and quickly brought back to the original designer. All in all, kickass.

Bootstrapping a 3D Printed Design is Profitable

The biggest question in my head for years has been this. Can you start a business with a desktop 3D printer? With a nice little Makerbot, or a RepRap and a really useful product design, can I actually be my own, cigar-sucking factory boss? In my own living room, with a bathrobe on? An intriguing thought, but do the numbers support such a possibility? As evidence show: YES! They decided to test the hypothesis of whether or not an entrepreneur can bootstrap their business by buying a cheap 3D printer and selling their one design. The part costs was a mere $13.40, roughly 60% of the full $19.95 price tag. Between December 2010 and September 2011, 42 orders of 51 Trik Adapters were printed by their Makerbot, plus 56 that were outsourced. Their conclusion was pretty simple. For the entrepreneur, 3D printing is a massive boon because the value of a product can be tested on the open market and quickly brought back to the original designer. All in all, kickass.

Bootstrapping a 3D Printed Design is Profitable