MX3D printing. DIY Selective Laser Sintering FAQ. Introduction Some time ago I started research on feasibility of building a DIY Selective Laser Sintering rapid prototyping machine to work with thermoplastics.

It quickly turned out that a there are quite a few enthusiasts who are already doing something in this area, as well as wealth of helpful information. However, what I found, it is very time consuming to gather enough background information to actually be able to design and build an SLS machine. So, I've started this FAQ with the aim to build easily accessible all-in-one collection of common answers to common questions so that other enthusiasts like me could save time looking for the same information.

Hopefully this becomes a living document as knowledge of the community grows. --Igor Lobanov 20:08, 27 June 2013 (UTC) Few simple rules are followed when working with the FAQ: Text taken from somewhere else (e.g. forum post) is shown as a block quote with a link to the original page and, if applicable, with the credit to its author. Markus Kayser - Solar Sinter Project. A Low-Cost Open-Source Metal 3-D Printer. A Low-Cost Open-Source Metal 3-D Printer.

Direct Metal Laser Sintering System Precious M 080 by CPM and EOS. Rapid Prototyping and Digital Sand Casting Services. YouTube. 3D printing. This article or section is incomplete and its contents need further attention.

Some sections may be missing, some information may be wrong, spelling and grammar may have to be improved etc. Use your judgment! Page created by Daniel K. Schneider, 14 October 2011Contributors: Daniel K. Schneider x245, Leapfrog x3, Edbri871 x1Last modified by Daniel K. 1 Introduction This article shortly introduces 3D printing principles and provides some advice on selecting a printer and then lists cheap open source and commercial 3D printers. 3D printer as geek campfire (Source:[1]) See also: Fab lab (for a wider technical picture) 3D printers in education and fab labs in education (for a wider picture in education) Printer-specific articles: Felix, RapMan, and Fabbster Software (listed below) Hobby milling (an alternative subtractive technology) (Micro) Fablab TECFA, our own little gear Slicers and user interfaces for 3D printers 1.1 3D printing technology The two most popular 3D printing techniques are:

Selective Laser Sintering - SLS. A brief review of the 3D printers of 2012. The avalanche of popular news stories has propelled 3D printing into the minds of consumers.

However, the major manufacturers of 3D printers have released a number of systems for professional uses. Here’s a quick look at what became available this year. A number of technical advances are demonstrated by this year’s new 3D printing systems. Sheet lamination using paper entered the market. A number of metal laser sintering companies established offices here in the U.S. Sheet lamination According to the ASTM International standard definitions, sheet lamination is a process in which sheets are bonded together to form an object. Primarily geared to form and fit applications, some industries can have paper objects serve as the final product. A Selectable Layer Thickness (S.L.T.) technique allows the printer to run in two different modes, draft or presentation.

The company also announced the Mcor IRIS, which prints in full 600 dpi color. ExOne Metal Printing Process. Selective laser sintering. An SLS machine being used at the Centro Renato Archer in Brazil.

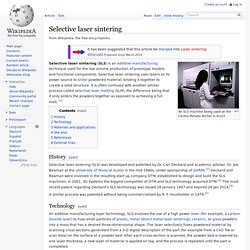

Selective laser sintering (SLS) is an additive manufacturing technique used for the low volume production of prototype models and functional components. Selective laser sintering uses lasers as its power source to sinter powdered material, binding it together to create a solid structure. It is often confused with another similar process called selective laser melting (SLM), the difference being that it only sinters the powders together as opposed to achieving a full melt. [1] History[edit] Selective laser sintering (SLS) was developed and patented by Dr. A similar process was patented without being commercialized by R. Technology[edit] A low cost open source laser sintering 3D printer. Lasers. An Open Source Laser Sintering 3D Printer. Additive rapid prototyping in plastic materials is becoming quite accessible to home and hobby users.

If you’re a hobbyist on a typical budget wanting to rapid prototype in metal, however, you’re limited to subtractive methods, i.e. CNC machine tools like mills and lathes, and even those are not exactly “cheap.” Professional 3D printing services like Shapeways offer additive metal prototyping in metals like stainless steel and gold, but it’s extremely expensive. The technology their 3D printers use, called “laser sintering,” is fundamentally different from the RepRap-type fused-filament (“robot hot glue gun”) 3D printers at the “garage” end of the pricing scale. In selective laser sintering (SLS), the object is built up in a bed of powder by a scanning laser beam that fuses tiny bits of the powder together, one layer at a time.

3D Printers.