Johnson Alex

Johnson Alex is an experienced digital marketer, who loves getting stuck into Google Analytics to look for opportunities, and thrives on finding ways to do things better.

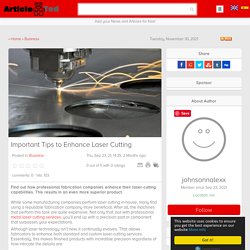

Weldflow Metal Products - Sheet metal enclosures Manufacturer in USA. Important Tips to Enhance Laser Cutting. While some manufacturing companies perform laser cutting in-house, many find using a reputable fabrication company more beneficial.

After all, the machines that perform this task are quite expensive. Not only that, but with professional metal laser cutting services, you’ll end up with a precision part or component that surpasses your expectations. Weldflow Metal Products - Stainless Steel Sheet Metal Fabrication in USA. How To Reduce Costs Of Steel Fabrication Without Compromising On Quality. Whether you perform fabrication services in-house and only use an outside source for certain services, or you completely outsource all of your fabrication projects, you’ll appreciate this information.

With this, you’ll learn to reduce the cost of stainless-steel fabrication without compromising its quality. Start With a Smart and Innovative Design. How to Achieve a High-quality Metal Enclosure Design. Often, manufacturers use metal enclosures inside or outside of their facilities.

Typically, they’re all made according to basic design principles. However, suppose you want new sheet metal enclosures of a higher caliber for your business. In that case, you’ll want to work with a reputable company that can make a product based on your specifications. Weldflow Metal Products - Get Custom Sheet Metal Fabrication in New York. Business Description Established in 1975, Weldflow Metal Products is one of the leading and most trusted manufacturers of precision metal products.

We have a committed team of experts who offer custom solutions to meet your needs and attain top level client satisfaction. We have become a trusted name and world leader in the field of contract manufacturing. Weldflow Metal Products - Laser Cutting in NYC. With the advancement of the world and new innovative advances making a wide margin, the requirement for custom machined parts & sheet metal laser cutting is expanding constantly.

New machines which require custom laser cutting services, specifically made to suit that purpose are in high demand. The estimation and measurements of these machine parts are not constantly consistent with standard qualities and thus they should be made independently by a laser cutting company for the particular reason. Find a company for laser cutting in New York and all neighbouring states who provides various sorts of metals beginning from aluminum to steel and are altogether cut into exact desired shapes with the use of this innovative technique. Weldflow has enhanced its metal laser cutting services in NYC and all other neighbouring cities and states across the USA by offering the following services: Laser Cutting Services.

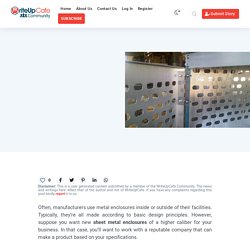

What Is The Maximum Thickness Of Metal That Lasers Can Handle? The Significance Of Custom Sheet Metal Fabrication. Although there are benefits associated with quality standard metal parts and components, customers enjoy even more with custom sheet metal fabrication.

With custom fabrication, a reputable manufacturing company produces a product based on the customer’s particular need. Sometimes, this involves custom cut metal shapes, uniquely engineered designs, a more complex metal, and so on. If you need to have a custom part or component manufactured, is it important to use the best sheet metal fabrication service possible.

As imagined, producing complex prototypes or custom finished metal products requires a high level of skill. That means the manufacturing company that you choose should have an in-house team of experts that offers years of experience, proper training and education, and substantial expertise in all fabrication processes. Weldflow Metal Products - Custom Sheet Metal Fabrication in USA. Established in 1975, Weldflow Metal Products is one of the leading and most trusted manufacturers of precision metal products.

We have a committed team of experts who offer custom solutions to meet your needs and attain top level client satisfaction. We have become a trusted name and world leader in the field of contract manufacturing. Our focus has always been on providing quality and effective products to our valuable clients.In our effort to satisfy the expectations of our clients, we are engaged in the manufacturing of a wide variety of precision metal products. With more than 40 years of global experience in the field of manufacturing and supply chain management, we have made continuous development.We offer a wide range of products including metal fixtures & enclosures, HVAC, appliance covers, part assemblies and much more.

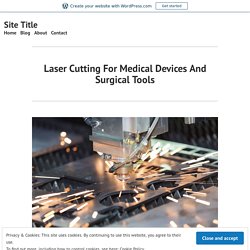

Laser Cutting For Medical Devices And Surgical Tools. Without question, laser cutting in New York has increased significantly over the past few years.

After all, this is an excellent way to produce precision products while keeping costs down. Some industries perform this in-house or outsource it to a reputable laser cutting company. Get Custom Sheet Metal Fabrication in New York. Custom sheet metal fabrication is currently in very high demand.

Sheet metal manufacturing companies are struggling to keep up with requests coming from the automotive, construction, and aerospace industries, among others. According to marketing experts, demand for the custom sheet metal fabrication process will continue climbing. Which Industries Benefit The Most From CNC Cutting. For custom-designed parts and components, manufacturers in different industries rely on CNC machines.

With automated and computerized motion control, this process yields precision results. However, when a manufacturer needs help, they depend on professional providers of CNC routing services. Which Industries Benefit the Most From CNC Cutting - How Metal Fabrication Is Revolutionizing the Healthcare Industry. Most people think metal fabrication is only for industries like construction, automotive, or aircraft. However, it’s now also a vital part of the health care industry. Today, top metal fabrication companies create parts, components, and entire products that allow medical professionals to provide patients with better care. Custom Sheet Metal Fabrication in USA - Weldflow Metal Products. Improve Efficiency And Quality Through The Fabrication Process. What Is The Process Of Cutting Mild Steel? Fabricators work on many different types of metal. One of these is mild steel, which is carbon steel with a low amount of carbon.

For that reason, it’s often referred to as “low carbon steel.” This versatile metal is ideal for many applications, including furniture, automobiles, signs, and more. For precision results, customers rely on professional laser cutting in NYC. For any business that uses mild steel and needs clean and consistent cuts, they’ll get the best results by turning to a trusted laser cutting company. Weldflow Metal Products - Sheet Metal Fabrication in USA. Established in 1975, Weldflow Metal Products is one of the leading and most trusted manufacturers of precision metal products.

We have a committed team of experts who offer custom solutions to meet your needs and attain top level client satisfaction. We have become a trusted name and world leader in the field of contract manufacturing. Our focus has always been on providing quality and effective products to our valuable clients.In our effort to satisfy the expectations of our clients, we are engaged in the manufacturing of a wide variety of precision metal products.

With more than 40 years of global experience in the field of manufacturing and supply chain management, we have made continuous development.We offer a wide range of products including metal fixtures & enclosures, HVAC, appliance covers, part assemblies and much more. Weldflow Metal Products - Sheet Metal Fabrication Companies in USA. Sheet Metal Fabrication: Tips From Master Fabricators. By Johnson Alex Blogger Meta Description: Get valuable information from top master fabricators. Learn about the sheet metal fabrication process and the various benefits it offers. If your company recently got into custom sheet metal fabrication, you probably have a ton of questions. Even if you have done this for some time, considering how quickly technology changes, you might want to make sure that you are up to speed on the latest options.

Fortunately, several top master fabricators shared valuable insights about precision sheet metal fabrication. How Does CNC Routing Work? Understanding CNC routing starts with learning the basic terms. CNC stands for computer numerical control, which means that a computer program tells the machine to cut a hole, preprogrammed shape, or design. When you complete the setup, the computer does all the programmed instructions.

Improve Efficiency And Quality Through The Fabrication Process. Importance Of Malleability And Ductility Of Metals In Precision Sheet Metal Fabrication. Sheet Metal Fabrication in USA - Weldflow Metal Products. A Checklist to Follow Before Working on a Steel Fabrication Project. Weldflow Metal Products - Stainless Steel Sheet Metal Fabrication in USA. Leaders in Custom Sheet Metal Fabrication - Weldflow Metal Products. Importance Of Malleability And Ductility Of Metals In Precision Sheet Metal Fabrication. What Are the Steps Involved in a Metal Fabrication Project? How Does CNC Routing Work? Sheet Metal Laser Cutting in USA - Weldflow Metal Products.

Weldflow Metal Products - Best Sheet Metal Laser Cutting Services in USA. Sheet Metal Enclosures in USA - Weldflow Metal Products. Ideal Companies To Fulfill Custom Fabrication Projects For Businesses. How Does CNC Routing Work? Choose The Right Custom Sheet Metal Fabrication – Weldflow Metal Products. Ideal Companies To Fulfill Custom Fabrication Projects For Businesses. Precision Sheet Metal Fabrication by Weldflow Metal Products.

How CNC Routers Make Sign Making Processes Easier. Why Is Steel Ideal For Metal Fabrication? Custom Sheet Metal Fabrication in USA by Weldflow Metal Products. Why Is Steel Ideal For Metal Fabrication? Precision Metal Fabrication Companies in USA – Weldflow Metal Products. Choose the Right Sheet Metal Fabrication Company in USA – Weldflow Metal Products. How Thick Metal Cutting Is Made Efficient With Lasers. The Basics Of Best Enclosure Designs. Metal Laser Cutting Services in USA - Weldflow Metal Products. Custom Laser Cutting Services in USA - Weldflow Metal Products. Design Custom Enclosures This Way To Get An Amazing Outcome. Weldflow Metal Products - Sheet Metal Companies. Trusted Laser Cutting Services by Weldflow Metal Products.

Sheet Metal Companies- Weldflow Metal Products. What Are The Factors That Impact Laser Cutting Services? Stainless Steel Fabricator Companies in USA - Weldflow Metal Products. Weldflow Metal Products - Precision Sheet Metal Fabrication. Design Custom Enclosures This Way To Get An Amazing Outcome. Steel Fabrication Services in USA – Weldflow Metal Products. High-Quality Stainless-Steel Fabricator Serving in USA - Weldflow Metal Products.

Types of Laser Machines for Different Applications. Weldflow Metal Products. Weldflow Metal Products - Laser Cutting nyc. Tips To Ensure Your Metal Enclosure Fabrication Projects Are A Success. Getting The Best Steel Fabrication Without Spending A Lot. CNC and Laser Cutting Services at Weldflow Metal Products. Custom Sheet Metal Laser Cutting Services in USA - Weldflow Metal Products. Improve Your Metal Fabrication with Laser Cutting Services - Weldflow Metal Products. Weldflow Metal Products - Precision Sheet Metal Fabrication. Weldflow Metal Products - Precision Sheet Metal Fabrication. Trusted Source for Sheet Metal Laser Cutting Services in USA - Weldflow Metal Products. Choose the Right Sheet Metal Fabrication Company in NYC – Weldflow Metal Products.

Turn to Weldflow Metal Products for Laser Cutting Services. Weldflow Metal Products -Metal fabrication nyc. Get Custom Metal Fabrication Services In New York – Weldflow Metal Products. Improve Your Next Metal Fabrication Project with Laser Cutting. Addressing a Few Common Myths Regarding Laser Cutting. Get Sheet Metal Enclosures At Weldflow Metal Products. Laser Cutting Services NYC – Weldflow Metal Products. What Makes Laser Cutting a Great Option? Metal Laser Cutting Services in USA - Weldflow Metal Products. Metal Laser Cutting Services in USA - Weldflow Metal Products.

Stainless Steel Fabrication Company in USA – Weldflow Metal Products. Metal Fabrication Companies in USA – Weldflow Metal Products. Custom Sheet Metal Fabrication Service in USA – Weldflow Metal Products. Weldflow Metal Products Reviews Weldflow Metal Products is a Metal Fabricators Company in New York Providing The Best Customer Satisfaction With Regards To Metal Fabricators Services. Hire A Metal Fabricators near 10001. How to Choose the Best Stainless Steel Sheet Metal Fabrication Provider from Alex Johnson -

What You Need to Know About Smart Packaging. Sheet Metal Companies in USA - Weldflow Metal Products. Sheet Metal Laser Cutting Services in USA – Weldflow Metal Products. Sheet Metal Laser Cutting Company NYC. Metal Fabrication: Increasing Your Process Efficiency. How to Get Your Ideal Metal Fabrication Services. Various Benefits of Using Steel for Fabrication. Why Collaboration Is Critical in the Metal Fabrication Industry. Various Industries Where Sheet Metal Fabricated Parts Are Used. Get laser cutting services in Canada at Weldflow Metal. Everything You Need to Know About Metal Fabrication. What Are the Applications of Metal Fabrications Across Various Sectors?

Advantages of Laser Cutting Metal Over Mechanical Cutting. Benefits of Steel Fabricators in Toronto for the Metal Industry.