All Kinds Of Fertilizer Crusher Machine. Different Types Fertilizer Granulator Machine. Fertilizer Machine & Production Line Manufacturer. Fertilizer machine and fertilizer production line manufacturers. Abstract This website pay attention to your privacy.

We will collect or use your information when you use our services. Fertilizer production line and fertilizer machine manufacturer-Zhengzhou Huaqiang. BB Fertilizer Production Line Manufacturer. The BB fertilizer production line is designed and manufactured according to the requirements of the compound fertilizer plant and fertilizer distributors.

The productivity can reach 10000 - 100000 tons per year. It uses the lifting tank to feed materials and mixer to load materials, that can achieve the effect of almost zero waste. The main body adopts positive or reverse motion mode, internal screw structure and three-dimensional structure to mix and convey materials. Organic Fertilizer Disc Granulation Production Line. Organic fertilizer disc granulation production line can process organic materials and produce organic fertilizer.The organic fertilizer disc granulation production line has the advantages of shortening production process, simple structure, less investment and easy operation, and is suitable for small and medium-sized enterprises.

The organic fertilizer disc granulation production line has rich raw material resources. The equipment may differ for different materials. 1.Animal waste, animal manure, such as chicken, pig, cattle, sheep, horse, rabbit, animal residue, and fish meal, bone meal, feather, fur, silkworm excrement, biogas residue, etc. 2.Agricultural waste. Crop straw, vine, soybean mean, rapeseed meal, cottonseed meal, caster bean meal, tea seed meal, yeast powder, mushroom residue, etc. 3.Industrial waste. Vinasse, vinegar residue, manioc waste, filter mud, herb residue, furfural residue, etc. 4.Municipal sludge.

Fertilizer Production Line manufacturer in China. New Type Two In One Organic Fertilizer Granulator,Combination Granulator. This new type two in one organic fertilizer granulator is a new patented product developed by our company and the Agricultural Machinery Research Institute.

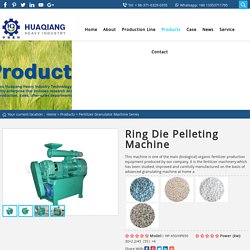

It is designed and manufactured with the new technology of wet continuous push rod granulation. The machine can granulate a variety of organic matter, especially for the coarse fiber materials which are difficult to be granulated by conventional equipment, such as crop straw, wine residue, mushroom residue, drug residue, animal dung and so on.The granulation can be made after fermentation, and can achieve a better effect of grain making to humic acid and municipal sludge. In the new type two in one organic fertilizer granulator, the first section of the machine is split type assembly without lifting device or manual dismantling. It is easy to clean the inner wall of the shell. Ex-factory price-ZhengZhou HuaQiang. This ring die pelleting machine is one of the main (biological) organic fertilizer production equipment produced by our company.

It is the fertilizer machinery which has been studied, improved and carefully manufactured on the basis of advanced granulating machine at home and abroad. The machine is excellent in technology and simple in operation, and designed with different models. It is an ideal processing machine for the organic fertilizer processing. Chain Compost Turning Machine. Double-screws Turning Machine-HuaQiang Heavy Industry. The double-screws turning machine is used for fermenting and dump of organic wastes such as livestock manure, sludge garbage, sugar factory filter mud, dregs cake and straw sawdust.

It is widely used in the fermentation and removal of water in organic fertilizer plant,gardening farm and BIS mushroom plant. It overcomes the limitation of the width and depth of the traditional groove turning machine. The turning depth can reach 1.6 meters and the turning width can reach 12 meters, which greatly improves the space utilization ratio. After the improved double axis reverse rotation movement, it has the functions of turning, mixing and oxygenation, improving the fermentation rate, decomposing the composting quickly, preventing the formation of the odor, saving the energy consumption of oxygen filling, and shortening the fermentation time.

Hydraulic Type Groove Turning Machine. INTRODUCTION Hydraulic Type Groove Turning Machines are widely used in the fermentation and removal of water in organic fertilizer plant, sludge waste plant, gardening farm and BIS mushroom plant.

The fermenting and dumping of organic wastes, such as livestock manure, sugar factory filter mud, dregs cake and straw sawdust. It is suitable for aerobic fermentation, and can be used with solar energy fermentation room, fermentation tank and moving machine. It can be used together with the moving machine to realize the function of many of slots for one machine. Simple Groove Turning Machine-HuaQiang Heavy Industry. Crawler type turning machine -HuaQiang Heavy Industry. Different Types Fertilizer Granulator Machine. Bio-organic Fertilizer Production Line Manufacturer. Huaqiang bio-organic fertilizer production line can deal with animal manure and crop straws etc into powder and granular organic fertilizer.The bio organic fertilizer production process mainly include the fermentation part and the production granulation part.

Even if the raw materials for organic fertilizers are better fermented, granulation is also difficult, because the characteristics of organic raw materials are rough raw materials, lighter, and lower bonding rate. Different organic materials have different characteristics. Therefore, when choosing equipment, you should take care. Fertilizer Machine & Production Line Manufacturer. NPK Fertilizer Production Line Manufacturer. We are China's professional NPK Fertilizer Production Line manufacturer.NPK Fertilizer Production Line can produce all kinds of concentration, multiple types of compound fertilizer.The main equipment that NPK Fertilizer Production Line contains: 1.Automatic batching machine 2.Belt conveyor 3.Mixer Machine 4.Crusher Machine 5.Rotary drum granulator 6.Dryer Machine 7.Cooler Machine 8.Screening machine 9.Coating machine 10.Packing machine NPK Fertilizer Production Line can produce all kinds of concentration, multiple types of compound fertilizer (including organic fertilizer, inorganic fertilizer, biological fertilizer, magnetized fertilizer, etc.) .

In particular, it can produce rare-earth, potash and ammonium bicarbonate series of compound fertilizer granulating. It fills the domestic blank and ranks the leading level in China. Organic Fertilizer Production Line Manufacturer. Organic fertilizer production line is often used to deal with different fermented organic matter into bio organic fertilizer.

We are leading Organic Fertilizer Production Line Manufacturer in China. One step method is used to produce organic fertilizer.With livestock and poultry waste and agricultural waste as the main raw materials, fecal or fecal waste not only created economic benefits for enterprises, but also made great contributions to human environmental engineering. The mainly equipment that organic fertilizer production line includes: Flat Die Granulator,flat-die granulator. The multifunctional flat-die granulator is a common used equipment in the production of organic fertilizer. It can produce cylindrical organic fertilizer particles and feed particles. It can also connect polishing equipment, making cylindrical particles to roll into balls, no rework, high balling rate, good strength and beautiful relocation. Disc Granulator,Pan Granulator. This disc granulator is a new type of tilting disc granulation equipment, its granulation rate can reach more than 95%.

The main gear of granulator is using high frequency quenching, so that its working life is doubled. The disc of the machine has a circular arc structure, which is lined with high strength glass steel, and the bottom of the disc is strengthened by a number of radiated steel plates. It is durable and never deformed. The thickened, heavier and stronger base does not need to be fixed with anchor bolts, and operates smoothly. The reducer and motor are driven by flexible belt, starting smoothly, slowing down the impact force and improving the operation life of the equipment. Rotary Drum Granulator. Rotary drum granulator is a molding machine that can make powder material into particle shape. Rotary drum granulator is one of the key equipment in the NPK fertilizer industry, which Iis suitable for large-scale production of cold, hot granulation and high,medium and low concentration NPK compound fertilizer.

The main working principle is granulating with wet granulation.Through a certain amount of water or steam, the basic fertilizer is fully chemically reacted in the cylinder after being humidified.In a certain liquid phase,the rotating movement of the barrel is helpful to make the material into ball by the extrusion pressure. The shell of the machine uses special rubber slab lining or acid-resistant stainless lining board which can realize auto scar removal and de-tumor instead of traditional drawknife equipment. New Type Organic Fertilizer Granulator. Huaqiang is a professional New Type Organic Fertilizer Granulator manufacturer in China.This series of new type organic fertilizer granulator is a new patented product developed by our company and the Agricultural Machinery Research Institute. It utilizes high speed rotary mechanical stirring force and the resulting friction force to make the powdery material continuous mixing, granulating, balling and intensifying inside the machine, to achieve the purpose of material granulation.

The machine can process a variety of organic matter after fermentation, t breaks through the traditional organic material granulating technology, and do not need to dry the raw materials. Roller Press Granulator. DZJ series roller press granulator is a new type of equipment developed on the basis of the original double rollers extrusion granulation machine according to the many years of our production experience. roller press granulator can be widely applied to fertilizer processing, feed production and chemical industry for granulation, production and processing of powder materials.

The belt is driven by an electric motor, and the transmission belt is transmitted to a pair of two high pressure rollers with sliding housing through the reducer to do relative work.The two rollers of the DZJ-I extruder interact with the relative work of the open gear, and the two rollers of the DZJ-II extruder is directly driven by two output axes on a special reducer to achieve the purpose of extrusion molding. Features of Roller Press Granulator: Huaqiang production line design.