hitechengineering

Hitech Engineering Services provides engineering design services such as CAD drafting, CAD conversion, mechanical product design, 3D CAD Modeling and millwork drafting services for Manufacturing, Furniture, Oil & Gas, Heavy Machinery, Automotive & Utility industry verticals. Hitech also offers Design Automation, Product Configuration and CPQ Solutions using state of the art DriveWorks software.

CAD Drafting for Fabricators: Your Complete Guide. CAD drafting holds utmost importance from design drafting and development to all the way through the manufacturing.

However, undertaking intricate and meticulous CAD drafting in-house can get challenging because of the limited resources and cost. Hence, outsourcing fabrication drawing to the professional CAD Company for profitability is a viable option as these drawings are the basis of the entire project. So, what exactly are fabrication drawings? Fabrication drawings encompass the detailed engineering guidelines for the shop floor and offer immense precision. Fabricators require fabrication drawings right from the design intent understanding to the parts manufacturing, assembly, and installation stages. Importance of Fabrication Drawings Fabrication drawings, apart from helping on shop floor have other applications as well. Top Most Outsourced CAD Drafting Services for Fabricators. CAD drafting remains an inseparable part of the fabrication industry given its acute importance from design development to manufacturing.

Detailed CAD drafting can thus become tricky but outsourcing CAD drafting services are there to you rescue. If you own a manufacturing or fabrication unit wherein you undertake fabrication projects for your clients, CAD drafting becomes your indispensable service. Why are Fabrication drawings indispensable for Fabricators. Manufacturing sector is on the cusp of two major (still ongoing) transformations – adopting new digitization technology and transforming legacy designs to CAD.

Fabricators are jumping on the bandwagon to explore the most efficient CAD drafting solutions as per their tooling capabilities. From furniture manufacturing to architectural components, and process equipment to sheet metal products, CAD shop drawings are an irreplaceable foundation to achieve quality deliverables. When the appropriate drafting platform, an expert CAD engineers’ team and the industry experts come together, detailed CAD drawings can be developed to ensure profitability and global competitiveness.

What is one advantage of 2D over 3D CAD drafting? Why Solidworks and Inventor Remain the Top Choices of the Shopfitting Industry. Shopfitting furniture manufacturing industry involves a significant amount of woodworking with precision.

Benefits of Adopting 3D CAD Modeling Services. How Product Configurators Can Resolve Challenges in Mass Customization. 3D product configurators give ETO manufacturers an edge over stand-alone CAD systems to ease product design customization, effectively meeting specific user needs for mass customization.

With rising mass customization in sheet metal fabrication industry, fabricators find it a herculean task to meet delivery schedules and maintain quality owing to active customer participation. Fabricators are in a dilemma to sustain process agility with design iterations because increased customization adds to design and manufacturing lead times. By developing product configurators, CAD models can be integrated with manufacturing machines to automate manufacturing tasks and achieve 99% quality. Also, by using interactive product configurator platforms, the buyer has an idea and a 3D view of the product before the placement of final order.

Engineering challenges due to mass customization: Shopfitting made easy with SolidWorks/Inventor. Creating customized furniture and fittings lie at the heart of the modern shopfitting manufacturing process.

Until now, shopfitting design engineers worked with CAD platforms like AutoCAD – popular for 2D CAD drawings – to create layouts, engineering drawings for production and other tasks. But this included spending huge time to generate cutting lists, project documentation, preparing veneer schedules and several other activities related to manufacturing. Introduction of parametric 3D software uprooted these processes and introduced new, efficient methods. Now simply exporting required dimensions like length, width, quantities of components, and thickness etc. are enough to automatically generate Bills of Materials (BOMs).

Benefits of 3D CAD modeling for metal fabricators industry. Kitchen Cabinet Drafting - Cabinet Shop Drawings for Kitchen. Non-trad Counter Drafting for School Commercial Cabinet Design Drafting Stainless Table Design for Commercial Kitchen Detailed Assembly for Kitchen Cabinet Kitchen Merchandizer Drafting for Commercial Cupboard Design Drafting for Commercial Office.

CAD Conversion Services – PDF to CAD and 2D to 3D CAD Conversion. Our 25+ years of CAD outsourcing services empowers us to deliver high-quality CAD drawings to industrial design engineers and manufacturing companies at affordable fees.

Our skilled draftsman creates permanent records of engineering designs in digital designs. Our CAD conversion services encompass: Outsource 3D CAD Modeling Services - 3D Modeling Company. 3D CAD Modeling: All that you need to know. Despite 2D drawings being the first choice for manufacturers, their shortcomings are fast pushing the industry towards 3D CAD modeling.

The latter has gained a wider acceptance on the shop floor as well as for design data exchange between various teams and across the enterprise. Challenges with 2D CAD Design intent communication gaps between designers and manufacturers.Inaccuracies during data exchange and fear of data loss during file conversion.Delayed production due to lack of timely information at production stage.

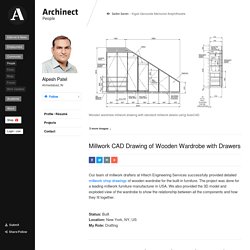

Recommendations. Millwork CAD Drawing of Wooden Wardrobe with Drawers. Anchor Wooden wardrobe millwork drawing with standard millwork details using AutoCAD 3 more images ↓ Our team of millwork drafters at Hitech Engineering Services successfully provided detailed millwork shop drawings of wooden wardrobe for the built-in furniture.

The project was done for a leading millwork furniture manufacturer in USA. We also provided the 3D model and exploded view of the wardrobe to show the relationship between all the components and how they fit together. Status: Built Location: New York, NY, US My Role: Drafting. CAD Data Integration with SigmaNEST for Sheet Metal Nesting. What are the benefits of custom furniture? Developed Product Configurator for Custom Door Manufacturer. Empowering B2B Sales with Product Configurator. Architectural Millwork Shop Drawings for Wooden Cabinet Drawer. 3D Model of Wooden TV Stand for living room on Behance. Millwork Design Drafting for Hotels & Restaurants. DriveWorks Implementation: Design Automation Services & Sales Configuration. Benefits of using a Product Configurator. Custom Joinery Design Services, Commercial Joinery Design. Importance of Kitchen Cabinet Design for Big and Small Kitchens. Creating a beautiful kitchen is everyone’s dream.

When it is about kitchen, the first thing that comes to everyone’s mind is the design of the entire kitchen and kitchen cabinets. In today’s trend, whether it is a small or big kitchen space, kitchen cabinets are an integral part of every new kitchen design and even kitchen remodel. Kitchen cabinet design includes everything right from the layout of your cabinets to the materials and finishes which are used to complete the overall look of the kitchen. If you are looking to renovate your kitchen, you may want to explore kitchen cabinet design ideas before starting the project. There are many things to take into consideration when planning your kitchen cabinets. What is Keeping Manufacturers from Shifting to 3D CAD? Despite more than a decade since the introduction of 3D CAD modeling in the manufacturing industry, right from giant manufacturing companies to small scale fabricators there are engineers and machine operators who still use 2D drawings.

To them, looking beyond the challenges in migrating to 3D is difficult. On top of it there are several myths about 3D CAD that pose as obstruction in adopting 3D modeling for shop floor needs. Manufacturing companies too are reluctant in making shift as they are unable to see beyond the myths of 3D CAD and give up their legacy of 2D drawing for shop floor needs, manufacturing communication, installation and assembly instructions and much more. And as a result, there is a hindrance that 3D solid models face to embed themselves in the manufacturing industry.

This article is an attempt to debunk the myth about 3D CAD in industrial designing and helping manufacturers take decision to make the shift. Importance of Casework Shop Drawings for Cabinet Makers and Architects. Building construction projects often involve a significant amount of work that concerns millwork and cabinet makers especially in a residential or an office project.

Everyone involved in the project, the furniture designer, millwork developer, and the architect, all of them have different opinions about designs and final fabrication calls. Casework or cabinets embedded as a part of the building need attention to all the details warehoused within the shop drawings. Designers or CAD drafters need to provide, enough information to carry out uninterrupted information. Why is it difficult to come to a consensus for casework shop drawings? When CAD draftsmen are working as an outside entity on a building construction project, there are a lot of opinion differences between architects and drafters. Also, when CAD drafters or drafting company for millwork is on a project with the construction firm, the architects insist to include the details according to their own needs. The Role of CAD Drafting Services in Mechanical Product Design. Computer Aided Designing (CAD) is a methodology in which computer technology is used for creating vector designs and 3D models that can be leveraged in various fields and industry verticals.

Are you having troubles creating accurate mechanical drawings using the traditional ways of drafting? Because, inaccurate drawings can cost you valuable time and money, as most firms realize the design flaws during the manufacturing stage, and are forced to revisit the design phase again. These firms claim they have lost millions of dollars and time just to fix a small but an error that was overlooked. Mechanical CAD drafting services can help you eliminate these problems and reduce design costs by increasing the overall design accuracy and eliminating the need for redundant designs. With the help of CAD, both 2D and 3D drawings as well as 3D CAD models can be produced, and this drawings can be rotated at any angle to view the details from a particular perspective.

Custom Millwork Shop Drawings for installation of Millwork Furniture. Reducing Red Lines in Cabinet Making with Custom CAD Configurator. A good cabinet maker knows redlines on drawings mean the designs are bettered with revisions. But a great cabinet maker knows ‘no-redlines’ mean the designs are done right with intensive inter-team communication. In fact such designs are developed as a result of tandem like coordination, centering on the customer needs, between the designer and the manufacturing shop engineer. But redlines are inevitable. Albeit product configurators have been around in the industry for a long while, redlines are seemingly non-destroyable when bespoke designs take the center stage.

Unsatisfactory drawings, unprecedented redlines To get it started, custom designs for furniture like cabinets or millwork furniture are prepared in the stagiest way possible. Ideally, the process is a one-go sketch with parametric CAD software, but it seldom happens. In order to reach a consensus, several revisions happen. Uncanny habits bring more than haywire process Fixation by designers to fix the bugs. When it comes to delays, should you really blame the metal fabricators? Importance of designing Sheet Metal Parts for uninterrupted Fabrication. Kitchen Cabinets Designing: Design How? Over Design What? Designs of kitchen layout have changed over the years. From a few shelves under the counter, an average looking storage box and a table to stylish modular kitchen cabinets, custom drawers and pull-outs upper and lower cabinets, the complete form and finish of the furniture has changed.

What details do you need and how you assemble each component is something that an architectural millwork designer would help you decide. Custom Furniture Design Services to increase Furniture Manufacturers deliverable quality. Advantages of CAD Configurator: Automate Quotation Documentation and Increase Revenue. With the increase in bespoke manufacturing needs the use of sales configurator or CAD configurator has increased. A CAD configurator allows customers to configure products to their exact requirements. CAD configurator is an interactive sales tool offering 2D drawings and 3D models, allowing customers to easily configure products or custom designs. DriveWorks Implementation: Automate your Design with DriveWorks & SolidWorks. Wooden Cabinets for Kitchen: The Best choices for Furniture Designers. Design Automation: Product Configurator Development & CPQ Solutions.

Custom Wall Mounted Cabinets: Unique Design to Fit your Space. You can optimize your space for a modern or contemporary design with LED lighting or create rich texture by using materials like metal, wood, and glass. There are an endless number of ways to truly create the style you desire while still staying within your budget. Modern Street Furniture Design: The New Trend in Furniture Industry. Designer street furniture for public places has become a new trend and that is why the demand for custom and modern designs of furniture has increased in recent times. Street furniture is mostly used in public places such as streets, plaza, waterfront, recreational area or a mall and more. In order to design street furniture, one must first plan, establish and define the type of space. Why is there A Need for Modern Office Furniture Design?

By hitechengineeringservices | On 30/01/2019 | Comments (0) Modern work space interiors demand flexibility and mobility. As a result, corporate and modern offices continue to evolve and adapt their workplaces with the change in technology. Modern day office furniture should reflect the work styles, company culture and progress. And hence modular furniture, which occupies less space, is the new emerging trend in for workspace designs. How to Address the Demand for Unique Cabinets & Casework Design.

Today, markets for kitchen cabinets and casework manufacturing are soaring high with booming innovations in commercial & residential architectural designs. However, delivering quality with custom & unique cabinet designs is not an easy job. CAD Configurator for Custom Doors to Achieve Right Design Mix. Door designing and manufacturing tasks seem to be simple with the possible geometrical dimensioning customization in length, breadth, and height. Modern Kitchen Cabinets Design - Enrich your Kitchen Space with Right Type of Cabinets. The kitchen is the soul of your living space, and an excellent place to express your personality.

How Retail Shop Furniture Design Services Helpful to Retail Stores & Chains? Customized Furniture Design: A Smart Choice for Attracting Right Customers. The requirement for unique & customized furniture has taken a new leap and that is why the custom furniture industry is booming. Cabinet Shop Drawings to Convey Design Details to Shop Floor. How to Choose the Best Furniture Design Services? As there are more & more modern offices and buildings to be built, the need for modern office furniture, custom furniture design will also grow to a new extent. Millwork Shop Drawings for Bespoke Furniture Manufacturer. Millwork Drafting Services: Importance of Offshore Service Provider. Offices and Institutional Furniture Design, Millwork Shop Drawings. Casework Shop Drawings: Millwork Drafting & Cabinet Drawings. CAD Drafting Services: Dependence of Retail Furniture Manufacturing Industry. Architectural Millwork Drafting: Custom Millwork Shop Drawing Services.

Benefits of Sheet Metal Design using SolidWorks. Benefits of SolidWorks Product Design and Development. How Custom Furniture Manufacturers can benefit using Furniture Design Services? How are Furniture Design services Helpful to Furniture Manufacturers? Design Automation Services to Improve Sales Quotation & Documentation. Tactfully using SolidWorks for Surface Modeling. How & Why Should you Convert PDF to CAD for Manufacturing Design Needs? 3D CAD Model for Automotive Industry. 3D Furniture Modeling & Rendering of Metal and Wooden Furniture. 3 Effective Benefits of 3D Modeling Services. CAD Designing and Drafting Services for Mechanical Product Design. How Sheet Metal Designers are the backbone of Fabricators? Why is Plant Design Engineering services important for Oil and Gas Industry? How SolidWorks Designers help develop Sheet Metal Part Designs rapidly and cost effectively.

3D CAD Modeling Services: SolidWorks 2D to 3D Solid Modeling. The Significance of Furniture Design services. Convert your Existing 2D Drawings to 3D CAD Models. All that you need to know about 3D CAD Modeling. Efficient 2D and 3D CAD Drafting for Fabricators & Manufacturers. How 3D CAD Modeling services help Different Industries? Why Fabrication drawings are important to Sheet Metal Manufacturers? Customizing Sheet Metal Products make you Lose Customers. How CAD can transform concepts into manufactured products? How Engineering Design Company helps Manufacturers? What are the Advantages of 3D Scan to CAD Conversion? Characteristics of an ideal Machine Drawing. Importance of CAD in Designing Process Engineering Equipment. Mechanical CAD Drawings - Changing the Domain of Mechanical Design. Benefits of Mechanical Drafting Services for Manufacturing Firms. Practical Applications and Benefits of the CAD Modeling Services. Importance of Sheet Metal Design for Fabricators.

Convert Your Designs to 3D CAD Models with Reverse Engineering. Predict Complex Behavior of Your Products with Simulation. Supporting Sheet Metal Product Design by Shifting from an Outsourcing to Productivity Partner. Putting More Engineering to Manufacture Safest Tornado Doors. Building Frugal Products Using CAE Tools for Emerging Markets. Removing Unnecessary Conservatism from Product Designs. Uniquely Crafted Furniture Designs That Are Inspired By Nature. 6 Reasons Why Reinforced Concrete Material Builds Better Structures…!!! BIM 4D for Construction Project Planning and Execution. Combining Parametric and Direct CAD Modeling Approach for Mechanical Drawings. CAD/CAE Enabled Mechanical Product Design Services; High Value Proposition for Your Business. Shop Drawings How to Manage Risks and Reduce Liability. Significance Of BIM For Civil Engineers In Respect To Road & Highway Design - Hi-Tech Engineering Services.

How BIM Helps Estimate Construction Costs and Save Money? Avoid Condensation Problems in Steel Frame Building Design.