Deltaschooloftrades. THE FIVE ESSENTIAL VARIABLES OF. Stick welding test part 2. Stick Welding Tips from Bubba. Lesson on welding thin steel, Oxyacetylene Welding/Brazing Excercises. Weldaluminum. Brazing & Soldering Knowledge Base. We've said that a brazed joint "makes itself" – or that capillary action, more than operator skill, insures the distribution of the filler metal into the joint.

The real skill lies in the design and engineering of the joint. But even a properly-designed joint can turn out imperfectly if correct brazing procedures are not followed. These procedures boil down to six basic steps. They are generally simple to perform (some may take only a few seconds), but none of them should be omitted from your brazing operation if you want to end up with sound, strong, neat-appearing joints. For the sake of simplicity, we'll discuss these six steps mainly in terms of "manual brazing," that is, brazing with hand-held torch and hand-fed filler metal. Brazing, as we've seen, uses the principle of capillary action to distribute the molten filler metal between the surfaces of the base metals. Note that the strongest joint (135,000 psi/930.8 MPa) is achieved when the joint clearance is .0015" (.038mm.) Instructables. WeldingGalvanized.pdf (application/pdf Object)

Questions and Answers for Tig Welding, Stick welding and Mig Welding. "Remember there is a new forum on the nav bar!..

" Tig Welding TipsMig Welding TipsStick Welding Tips Stick, Mig, Tig Welding Questions, and Answers Question:... I just acquired a lincoln AC 225 amp arc welder a few days ago. I have been playing around with some scrap metal and some 6011 rods, but really have no idea what i am doing. AnswerAt your level, just striking an arc without sticking , and then running a straight bead is the first thing to learn. I will tell you that the number one thing that virtually everyone does wrong when they first stick weld is to hold too long an arc. Make sure the machine is hot enough so that when you hold a very tight arc…the rod wont stick..like a close enough arc that you can feel the tip of the rod dragging the metal. Then just move the puddle along slow and steady. Question: how can I get better ground with the standard ground clamp for mig welding? Now you have a cool tool that gives you a constant ground. Thnks for your question. Your question; Jody. Improving Your Skills - MIG Welding.

Wire Feed Speed. MIG Welding Tips - Intro. MIG Welding Principles. How to Mig Weld - Down and Dirty Tips. Home. Classic Broncos .com - Home Made TIG Welder * 66-77 Early Ford Broncos. I guess you could call this a Junkyard Tig Welder.

The idea is you can mount a regular Ford 130 amp 3G style alternator on to your air compressor (or similar motor) so that you can use the belt drive off of the compressor to turn the alternator. Using a battery jumpstart box to give the field its current, then regulate the current through a headlight dimmer switch. Then hook your Tig torch up to the case of the alternator and run the ground clamp to the output stud. Basically the motor from the compressor will be able to spin the alternator fast enough (approximately 6000-7000 RPM's) to generate the necessary power.

You will probably have to put a v-style pulley on the alternator for sufficient tension. Fortunately alternators are rated for 100% duty cycle so once you get it started (you have to scratch start it) it can keep going. Tech article by Richard Burris (ricks77eb) WELDING and CUTTING. The At Home Welder. Hooper Welding Supply - Tip Charts.

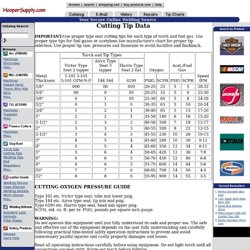

Cutting Tip Data IMPORTANT: Use proper type seat cutting tips for each type of torch and fuel gas.

Use proper type tips for fuel gases or acetylene.See manufacture's chart for proper tip selection. Use proper tip size, pressures and flamesize to avoid backfire and flashback. Type 101 etc. Victor type seat, tube mix lower psig. WARNING: Do not operate this equipment until you fully understand its safe and proper use. Read all operating instructions carefully before using equipment. WARRANTY CLAUSE: Uniweld believes the information contained herein to be reliable. Weld/Braze Tip Data IMPORTANT: Use proper type of tip for each type torch. How to Weld - MIG Welding. MIG welding was developed in the 1940's and 60 years later the general principle is still very much the same.

MIG welding uses an arc of electricity to create a short circuit between a continuously fed anode (+ the wire-fed welding gun) and a cathode ( - the metal being welded). The heat produced by the short circuit, along with a non-reactive (hence inert) gas locally melts the metal and allows them to mix together. Once the heat is removed, the metal begins to cool and solidify, and forms a new piece of fused metal. MIG Welding - The DIY Guide. How to Weld - TIG Welding. Making Hinges.