Guardian Sustainable Business. Waste is so last season: recycling clothes in the fashion industry. So, which textiles can be recycled and how?

“The key differentiation is between ‘mechanical fibre recycling’, which will degrade with each recycling (down-cycling) and ‘chemical fibre recycling’ which in some cases can produce fibres of equal quality to virgin ones” explains senior research fellow, Textiles Environment Design, Kate Goldsworthy. Mechanical recycling of natural fibres like cotton and wool is currently the most scalable recycling technology for post-consumer textiles but the result is shorter textile fibres of a lower quality to virgin fibres, adds Carola Tembe, H&M’s environmental sustainability co-ordinator.

To increase quality, recycled fibres must be blended with virgin fibres. Forget about cotton, we could be making textiles from banana and pineapple. Cotton makes up a third of fibre consumption in the textile industry, according to a global apparel fibre consumption report (pdf) published in 2013.

The cotton production industry is labour intensive and involves a lot of sweat, chemicals and fresh water. Could a number of innovations from natural sources and raw materials compete with the unsustainable product of the cotton plant? Natural dyes v synthetic: which is more sustainable? “I have workers in my factory who spend two to four hours everyday going to collect water, with no guarantees they’ll even find it,” says Sonal Baid, founder of Aura Herbal Wear, who blames synthetic dye factories for polluting local water sources.

Baid and her husband, Arun, have figured out how to use natural dyes at scale at their factory in Ahmedabad, India. Now, they want to convert India’s textile manufacturers, taking them back to natural dyes on natural fabrics, a tradition that Baid said was commonplace in the country until 40 years ago, when synthetic dyes took off. Discovered in the mid-19th century by English chemist William Henry Perkin, mauveine, the first man-made colour, transformed textile manufacturing. These synthetic colours allowed manufacturers and dye houses to operate in large quantities, and offer vivid, rich colours. They became the go-to option; they stick to fabrics easily, don’t lose pigmentation, and offer a limitless palette of colour options. Can a hashtag change the fashion industry? Nike and Adidas show cautious support for eco-friendly dye technology.

It has been a significant step forward for the textile sector.

Up until now the effluent from dye houses that can often be seen in rivers flowing through the textile manufacturing areas of India, China and elsewhere is a result of unabsorbed dyes, chemicals and heavy salts that are used during the dyeing process. A number of companies, DyeCoo, ColorZen and AirDye have set out to address this pollution by designing waterless dye technology. The result is a reduction in wastewater, energy, chemicals and toxic discharge to such a degree that it could revolutionise the textile industry. Major brands including Nike and Adidas have been integrating waterless dye technologies into their product lines, but costs and limitations have experts in the textile industry worried that the support will not last.

Two years after Rana Plaza, have conditions approved in Bangladesh’s factories? On 24 April 2013, an eight-story garment factory collapsed in Dhaka, the capital of Bangladesh.

The building’s fall killed 1,134 people and injured hundreds of others. Birmingham City University - Sign In. Birmingham City University - Sign In. NRG Made This ‘Shoe Without a Footprint’ from Power Plant Emissions. It’s no mystery why an energy company might explore applications for gaseous waste emitted from its power plants, but making shoes isn’t usually on the agenda.

For NRG, shoes made from carbon dioxide emissions are just the beginning. NRG began making its “Shoe Without A Footprint” sneakers by capturing effluent from power plants, cooling it, and separating out the carbon dioxide. The carbon dioxide then becomes the base of a chemical that is used to create the polymer that forms the shoe’s supportive foam.

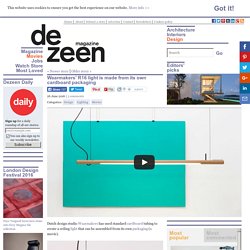

Waarmakers' R16 light is made from cardboard packaging. Dutch design studio Waarmakers has used standard cardboard tubing to create a ceiling light that can be assembled from its own packaging (+ movie).

The R16 lamp is delivered in a cardboard cylinder that contains the various components needed to transform the tube into a light – thereby reducing waste. The cardboard tube has a central perforated section, which is laser cut. After the cylinder is unwrapped, this section can be removed to leave room for the lightbulb to shine through. How Cotton Recovery is Changing the Game for Sustainable Fashion. How can we sustainably shape the world of the future?

How can we consume with a clear conscience? What shape does effective recycling take? These are a few of the questions that we all have to ask ourselves in light of the fact that raw materials are finite and we’re using up this planet’s resources like we have another one to go to later. I:CO believes it has found the answer to these questions, one proved by nature herself. Just as nature reuses everything that it produces, I:CO (short for I Collect) has created a closed-loop system in which textiles and shoes can be recycled and remade into new products. The fashion industry is the second most polluting industry in the world, next to big oil. Plastic bag charge: Could fee be applied to other packaging? Image copyright Thinkstock A 5p charge for plastic bags in large stores was introduced in England a year ago next week, and research suggests it's had positive environmental effects with usage radically reduced.

Some 90% of shoppers in England now use their own carrier bags, research for Cardiff University has suggested - up from 70% before the levy was introduced. This follows similar results in Scotland, Wales and Northern Ireland.