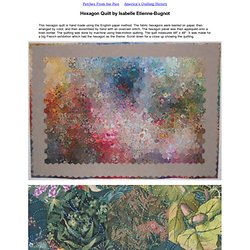

Hexagon Quilt by Isabelle Etienne-Bugnot. Hexagon Quilt by Isabelle Etienne-Bugnot Return to Quilting in France: A Revival of Interest by Isabelle Eteinne-Bugnot Discover the history of hexagon quilts at Hexagon Quilts From the Honeycomb to Grandmother's Flower Garden.

Portland cement. A pallet with Portland cement Portland cement clinker is a hydraulic material which shall consist of at least two-thirds by mass of calcium silicates (3 CaO·SiO2 and 2 CaO·SiO2), the remainder consisting of aluminium- and iron-containing clinker phases and other compounds.

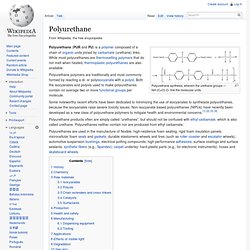

The ratio of CaO to SiO2 shall not be less than 2.0. The magnesium oxide content (MgO) shall not exceed 5.0% by mass. Polyurethane. Polyurethane synthesis, wherein the urethane groups — NH-(C=O)-O- link the molecular units.

Polyurethane (PUR and PU) is a polymer composed of a chain of organic units joined by carbamate (urethane) links. While most polyurethanes are thermosetting polymers that do not melt when heated, thermoplastic polyurethanes are also available. Polyurethane polymers are traditionally and most commonly formed by reacting a di- or polyisocyanate with a polyol. Both the isocyanates and polyols used to make polyurethanes contain on average two or more functional groups per molecule.

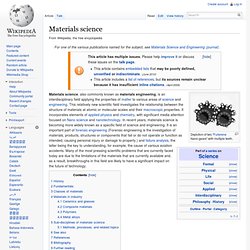

Some noteworthy recent efforts have been dedicated to minimizing the use of isocyanates to synthesize polyurethanes, because the isocyanates raise severe toxicity issues. Polyurethane products often are simply called “urethanes”, but should not be confused with ethyl carbamate, which is also called urethane. Materials science. Depiction of two "Fullerene Nano-gears" with multiple teeth.

Materials science, also commonly known as materials engineering, is an interdisciplinary field applying the properties of matter to various areas of science and engineering. This relatively new scientific field investigates the relationship between the structure of materials at atomic or molecular scales and their macroscopic properties. It incorporates elements of applied physics and chemistry, with significant media attention focused on Nano science and nanotechnology.

Cryogenic grinding. Cooling system of a cryogenic grinder An Example of a solenoid powered cryogenic grinder How cryogenic grinding with a solenoid works Cryogenic grinding, also known as freezer milling, freezer grinding, and cryomilling, is the act of cooling or chilling a material and then reducing it into a small particle size.

For example, thermoplastics are difficult to grind to small particle sizes at ambient temperatures because they soften, adhere in lumpy masses and clog screens. Stock Material. Fullerene. The discovery of fullerenes greatly expanded the number of known carbon allotropes, which until recently were limited to graphite, diamond, and amorphous carbon such as soot and charcoal.

Buckyballs and buckytubes have been the subject of intense research, both for their unique chemistry and for their technological applications, especially in materials science, electronics, and nanotechnology. History[edit] The icosahedral fullerene C540, another member of the family of fullerenes. Wootz steel. Swords manufactured from crucible steels, such as wootz steel, exhibit unique banding patterns due to the intermixed ferrite and cementite alloys in the steel Wootz steel is a steel characterized by a pattern of bands or sheets of micro carbides within a tempered martensite or pearlite matrix.

It is the pioneering steel alloy matrix developed in South India in the sixth century BC and exported globally. It was also known in the ancient world as Seric Iron. History[edit] The Wootz steel originated in South India and Sri Lanka.[1][2] There are several ancient Tamil, Greek, Chinese and Roman literary references to high carbon Indian steel since the time of Alexander's India campaign. The Tamilakam method was to heat black magnetite ore in the presence of carbon in a sealed clay crucible inside a charcoal furnace. History of ferrous metallurgy. Ferrous metallurgy involves processes and alloys based on iron.

It began far back in prehistory. The earliest surviving iron artifacts, from the 5th millennium BC in Iran and 2nd millennium BC in China, were made from meteoritic iron-nickel.[1] By the end of the 2nd millennium BC iron was being produced from iron ores from South of the Saharan Africa to China.[2] The use of wrought iron was known in the 1st millennium BC. During the medieval period, means were found in Europe of producing wrought iron from cast iron (in this context known as pig iron) using finery forges. For all these processes, charcoal was required as fuel. Mobile Machine Shop US Army 1943.jpg - Wikipedia, the free encyclopedia. Milling machine. Milling is the machining process of using rotary cutters to remove material from a workpiece advancing (or feeding) in a direction at an angle with the axis of the tool.

It covers a wide variety of different operations and machines, on scales from small individual parts to large, heavy-duty gang milling operations. It is one of the most commonly used processes in industry and machine shops today for machining parts to precise sizes and shapes. Face milling process (cutter rotation axis is vertical) Milling is a cutting process that uses a milling cutter to remove material from the surface of a workpiece. The milling cutter is a rotary cutting tool, often with multiple cutting points. The milling process removes material by performing many separate, small cuts.

Turning. Roughing, or rough turning Parting aluminium Finish turning Turning can be done manually, in a traditional form of lathe, which frequently requires continuous supervision by the operator, or by using an automated lathe which does not.

Belt grinding. Applications[edit] Belt grinding is a versatile process suitable for all kinds of different applications. There are three different applications of the belt grinding technology: Friction drilling. The basic steps in the friction drilling process: 1. Tool 2. Heat 3. Screw thread tap Friction drilling is a method of making holes in metal in which the material is pushed out of the way with the aid of heat from friction. The process is also called thermal drilling, flow drilling, form drilling, or friction stir drilling.[1] History[edit] In 1923, the Frenchman Jean Claude de Valière tried making a tool that could make holes in metal by friction heat, instead of by machining. It was not until the 1980s that a useful tool could be produced. Principle[edit] Advantages[edit] Very quick process (2 to 6 seconds)[2]The process reshapes all material so that no material is lost. Casting (metalworking) Casting iron in a sand mold Casting processes have been known for thousands of years, and widely used for sculpture, especially in bronze, jewellery in precious metals, and weapons and tools.

Traditional techniques include lost-wax casting, plaster mold casting and sand casting. The modern casting process is subdivided into two main categories: expendable and non-expendable casting. It is further broken down by the mold material, such as sand or metal, and pouring method, such as gravity, vacuum, or low pressure.[2]