What's the Best Steel? All Text, Graphics, Animations, Video, and Commentary on this website was created by, and is the intellectual property of m4040@m4040.com.

All Rights Reserved. Unauthorized reproduction is punishable by up to a $500,000 fine or 5 years imprisonment for a first offense, and up to a $1,000,000 fine or up to 10 years imprisonment for subsequent offenses under the Digital Millenium Copyright Act (DMCA). Requests for use of this material should be forwarded to m4040@m4040.com. What Is the Best Blade Steel? What is the best blade steel? Where Do These Steel Designations Come From? Here's a little factoid for you blade aficionados out there... and I'm going to get a lot of crap-filled emails protesting this point, but here goes... I know that may be a bit surprising to many blade enthusiasts, but it's true.

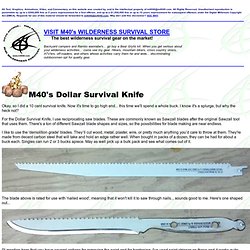

The Problem With Picking the "Perfect" Blade Steel As for the various blade alloys, each has it's benefits and each has it's drawbacks. What Is Steel? How Are Blades Processed? Final Thoughts. M40 Project - Dollar Survival Knife. M40's Dollar Survival Knife Okay, so I did a 10 cent survival knife.

Now it's time to go high end... this time we'll spend a whole buck. I know it's a splurge, but why the heck not? For the Dollar Survival Knife, I use reciprocating saw blades. These are commonly known as Sawzall blades after the original Sawzall tool that uses them. I like to use the 'demolition grade' blades.

The blade above is rated for use with 'nailed wood', meaning that it won't kill it to saw through nails... sounds good to me. I'll mention here that you have several options for removing the paint and for hardening. While I typically harden and then temper these, I will mention that they do okay with no additional hardening. So here's my blade after a trip to 2000+ degrees and a water quench (blade only)... ...and after some cleanup and tempering. The possibilities for handles, sheaths and finishes are near endless. Here's a wood and metal rated blade next to one that's been blued and roughed out.

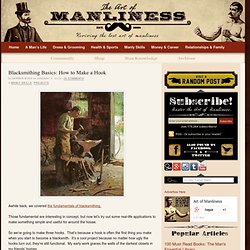

Good Luck! Blacksmithing Basics: How to Make a Hook. Awhile back, we covered the fundamentals of blacksmithing.

Those fundamental are interesting in concept, but now let’s try out some real-life applications to make something simple and useful for around the house. So we’re going to make three hooks. That’s because a hook is often the first thing you make when you start to become a blacksmith. It’s a cool project because no matter how ugly the hooks turn out, they’re still functional. My early work graces the walls of the darkest closets in my friends’ homes. Because this is a pretty fluid medium and static pictures aren’t able to convey the process very well, I’ve composed a short video showing the elements of the skills and forces needed to create a hook (not necessarily in order).

The reason things may not be in order is because I often had three irons in the fire. Hook A (a scroll tip – the middle one) is what you’d make if you want a little more surface area so if you hung a coat on it, the hook wouldn’t dig into the fabric or liner.