Fiberworks International

If you can imagine it we can build it. We build Bodies of Electric Tricycles, School Furniture, Garbage Bins, Underground / Overhead Tank, Pool Slides and Lounges, Fiberglass fishing boat, Basketball Boards, Park Benches, Retail Kiosks, Office Furniture, Household Furniture, Statues of all Sizes, Airsoft mask, Car body kit, Caricatures, Model boats and More!

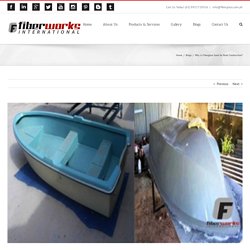

Why is Fiberglass Good for Boat Construction? - Custom FIberglass Product PH. In the past, aluminum used to be the preferred material for boat hulls.

Not anymore because fiberglass has taken over. At first, it may not look like a suitable material for building boats and marine products. But, it’s the truth and many vessel-builders now choose to work with this strengthened plastic material made from glass fibers. Composite fiberglass has multiple advantages over wood for construction of the boat’s superstructure or body. Yes, it’s cheap because the cost is roughly ⅓ of the expense for wooden vessels. The material is sturdy so hulls may be thinner than the average thickness. How does it work? What’s the catch here? What Makes a Fiberglass Swimming Pool Better? - Custom FIberglass Product PH. Swimming pools are manufactured from different materials.

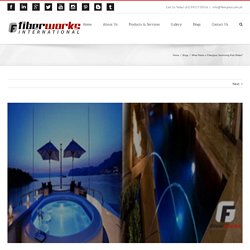

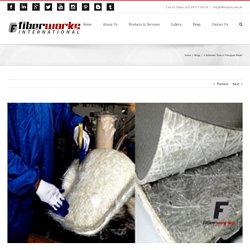

All kinds of materials both have pros and cons but fiberglass is becoming more popular for many reasons. With the pool made of fiberglass, installation is faster and much of the fabrication is done in the plant before being transported to the site. Standard installation can be finished within 7 to 14 days. On the contrary, concrete pools require many weeks or months before these can be completed and used. A Refresher: How is Fiberglass Made? - Custom FIberglass Product PH. Fiberglass comes from an assortment of processed chemicals and natural inorganic substances.

Its main elements include limestone, silica minerals (composed of oxygen and silicon), and soda ash or sodium carbonate. Silica sand comprises the oxide that promptly forms the glass while sodium carbonate with limestone reduce melting temperature. Borax is added to increase resistance against chemicals. Glass waste, on the other hand, is used as raw material. Unprocessed ingredients are weighed in specific quantities and blended prior to being melted into glass. The Convoluted System. Why Fiberglass: Upsides of using Fiberglass for Fabrication - Custom FIberglass Product PH. All of a sudden, fiber-reinforced materials have created a significant impact among business owners and stakeholders in various industries.

These include construction, waste water engineering and treatment, theme parks, and resorts. How does fiberglass perform against other traditional materials like concrete, aluminum, and steel? Consider the following: Explore Our Fiberglass Custom Products. Custom Made Fiberglass Airsoft Mask. Fiberworks has become in recent years one of the most innovative, dynamic and fun companies in the sector.

Fiberglass Boats & Marine Products. Just as people say today, “If you want to buy a luxury yacht that is designed by a famous designer, you go to Italy, but if you are looking for a yacht that is built with high quality and acceptable price, you can Find one in Fiberworks.

Fiberworks has been dedicated to the design and manufacture of boats and the development of their technologies in order to remain competitive in the market. Amusement Ride Manufacturers. Fiberglass.com.ph realizes that lightweight materials like reinforced fiberglass contributed immensely to the development of a multitude of amusement rides.

We have kept in step with this remarkable advancement by honing our capabilities in design, engineering and fabrication of fiberglass amusement rides. Our company makes use of modern technology and techniques which include innovative designs and detailed creative processes. The amusement park industry continues to evolve so we also take into account the public’s enjoyment and safety. Aside from using sturdy and strengthened fiberglass, we also utilize fortified support systems and headrests, comfortable pads, ratchet straps, seat dividers, magnetic brake systems, and computerized controls.

Custom Made Fiberglass Swimming Pool & Jacuzzi. The pools and Jacuzzi made with fiber, also plastics or polyester, perfectly fulfill their mission.

In addition to providing comparative benefits with other manufacturing methods. Fiber pools are usually one of the best options in price/performance. The quality of these as in all gadgets depends on manufacturers, thickness, finishes, and trim. Having the buyer within an economic field a selection of offers quite broad. In this portal, you can find information on this type of swimming pools. Fiberworks is a company dedicated to the design and manufacture of fiberglass pools and Jacuzzi, with the aim of providing quality swimming pools and latest generation equipment to achieve customer satisfaction at a lower cost.

Its mission is to offer customers the opportunity to have a pool at home or business with innovative design and quality that deserves, fulfilling their requirements and demands, and that can enjoy the comfort and safety in a family that our pools offer. Custom Fiberglass Products. We at Fiberglass.com.ph know that interior design has gone through a very drastic revolution since the 1990s.

Notable progress was made in terms of creative techniques, data application, and building performance are calling for new interior design expertise. Designers have perfected their craft to create practical and wonderful spaces. These range from rewriting the interior landscape, preservation of history and flexibility to novelty in newly-built spaces. All these are intended to meet requirements of ever-changing working-and-living models. Design entrepreneurs have shifted the delivery of their creative services into virtual reality. Custom Fiberglass Made Products. We work with clients determined to impact and sell, so we offer our experience in the development of sculptures, floats, decoration.

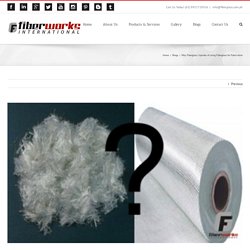

We repair and manufacture figures and sculptures in figures in fiberglass in almost any material or size, the limit is your imagination. At Fiberworks we are a company with years of experience providing solutions in the current market, participating in projects of various kinds, which makes it a competitive company at an international level. Fiberglass is a material that results from a very thin strand of filaments based on silicon dioxide.

Among its most important properties is that it is an excellent thermal insulation, due to its high surface area in relation to its weight (very light); Therefore, the blocks of fiberglass easily catch the air or the wind between them. In addition, because of the great ductility that counts (ability to deform without breaking), this material holds much tension and is very resistant to blows. Fiberglass Furniture Manufacturer. Fiberglass.com.ph customizes hardy, classy and affordable furniture made from fiberglass. No doubt we can compete even with big corporations across the world. One of our landmark achievements is the use of raw fiberglass to fabricate custom-built furnishings. This unprocessed composite material is made from imported resin and fiberglass. We conducted extensive research on their properties and made some upgrades to strengthen the material.

Life Size Fiberglass Sculptures. Your favorite action character, product or logo transformed into high-quality fiberglass figures In our company, we have a team of sculptors who will work on your character, product or logo with an excellent quality. Our fiberglass figures are manufactured to meet your needs for use, durability, and projection. For exterior or interior, for a day or a year, for light use or rough use, with lighting or movement, you choose how and where you want to see your fiberglass figure and we will make it a reality for you. About Fiberworks. Home of Fiberworks has expanded operations globally. Fiberworks is the #1 Fiberglass Fabrication company in the Philippines.

The elite members of the Fiberworks senior partners have over 30 years of Fiberglass Fabrication experience. The company have completed over 175 various projects across the Philippine peninsula and worked with over 50 clients in the Philippines. Fiberworks has completed over 20 Million pesos in Fiberglass related projects with some of the most prestigious organizations in the Philippines. The Ayala Corporation, SM and News TV5 are just a few of the 100s of clients that Fiberworks has serviced in the last 5 years. Despite the humble beginnings of Fiberworks, the company has continued to grow by leaps and bounds. Many companies charge much higher fees only to provide substandard quality.

Suppliers of Fiberglass Products from Philipines - FRP Sheets.