Darr Equipment Co. offers a variety of material handling & construction solutions & services to help our customers improve efficiency & profitability.

Warehouse Solutions: Robotic Industrial Sweepers/Scrubbers & ASRS. These automated machines are designed to reduce labor costs, improve efficiency, accurately measure performance, and increase safety, making them an attractive option for businesses that value major technological innovation.

These revolutionary material handling tools include everything from automated storage-retrieval systems (ASRS) to autonomous robotic industrial sweepers and scrubbers. Keep reading as we delve into the ins and outs of these two warehouse equipment solutions that you can integrate into your facility for a better bottom line. The traditional manual approach to cleaning warehouses just doesn’t seem to cut it anymore, as your employees and customers have heightened expectations regarding their health and safety – especially since the dawn of the Coronavirus pandemic. Automated storage and retrieval systems are automated systems that are designed to store items efficiently and securely in a compact footprint. Fleet Track & Forklift Rental: The Perfect Pair. Renting lift trucks minimizes the demands on cash flow, eliminates the possibility of investing in obsolescence, and keeps their bank credit lines open.

With that said, enterprises with capital budget constraints are not the only forklift rental aficionados in the material handling industry. In fact, renting industrial vehicles is also an attractive option for businesses that use their equipment heavily (more than 1,500 hours per year) or have the potential for changes in their product specifications (such as going from handling smaller goods to large, heavy items). Although it might be true that renting is a smart move for your company in terms of money and/or logistics, there are still several pros and cons that should be considered before you lease. The Challenges of Renting Lift Trucks. Poor Used Pallet Racking Practices. When done right, optimizing your warehouse shelving can increase your storage space and improve productivity.

There are many options when it comes to purchasing, installing, and maintaining your pallet racking. Unfortunately, with this seemingly endless number of options comes more room for error. Keep reading as we discuss seven of the most commonly made storage mistakes, from choosing a bad layout from the get-go to engaging in poor used pallet racking practices and more. 1. Picking the Wrong Design. Easy Integration of AGVs with Industrial Pallet Racks. Automated guided vehicles (AGVs) are making their debut in many warehouses throughout the United States.

Their quiet, clean, automatic-guided material handling capabilities make it easy to see why they are a popular choice among warehouse managers. Moreover, integrating guided vehicles into your facility allows for more accuracy and efficiency for order fulfillment, a reduction in operating costs, and the elimination of staffing issues caused by the industry’s high turnover rate. All of these factors make AGV technology a real star. However, when making the transition to AGV equipment, it’s not just about the vehicles themselves. In fact, a well-thought-out warehouse configuration is a fundamental factor in leveraging the benefits that AGV technology has to offer. Careful design consideration is essential when integrating guided vehicles into your specific storage system. Before we get started, it is important to understand that not all AGVs are created equal. Valuable Solutions for Fleet Track Management. Managing a pool of industrial vehicles can be a challenge even in the best of times.

Add external influences that managers have little control over – like new legislation, rising costs, and even crises that can affect the supply chain (such as the Coronavirus pandemic) – and fleet management can soon become seemingly impossible. Luckily, there are valuable solutions that forklift service companies can offer to help fleet managers make the task less unwieldy. Many of these solutions involve helpful software that works to coordinate fleet management activities and support the role of the manager. Keep reading as we delve into the purpose and challenges of fleet management, along with how Darr Equipment’s Fleet Track software can set your warehouse up for success.

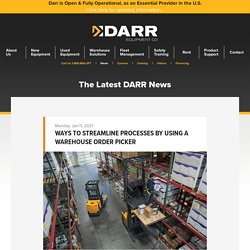

Ways to Streamline Processes by Using a Warehouse Order Picker. Because today’s consumers have become increasingly accustomed to receiving their goods extremely fast, businesses of all sizes – from mom-and-pop shops to large corporations – need to streamline their order picking practices in order to deliver products in the most efficient manner possible.

This is especially true for enterprises that rely on warehouse staff or automated equipment to fulfill orders. So, what exactly does order picking entail? Order picking is essentially the labor required to pull an item from inventory to fulfill a customer’s order. While this may seem like an easy procedure, you might be surprised to learn that an average of 55 percent of operational costs in distribution centers are focused on order picking. In other words, warehouses with ineffective systems could halt further innovation, stunting company growth. Forklift Repair: DIY Could Mean Disaster. Have you ever heard any horror stories about fleet managers trying to maintain their own forklifts?

Or have you heard the tales of irresponsible maintenance routines that are essentially founded on the idea of waiting for something to break before addressing the issue? Maybe you have actually experienced these circumstances yourself – and if so, have you been the perpetrator in either of these scenarios? How to Fix 3 Common Forklift Repair Issues.

Forklifts are the workhorses of the material handling industry – and rightfully so.

Their popularity can be attributed to their versatility and durability. Winter Forklift Maintenance Tips. Winter is coming – is your lift truck ready?

While most warehouse managers understand the importance of regular forklift maintenance, not all of them remember to take extra care of their fleet when the colder months come rolling in. Regardless of whether you choose to let a forklift service company take care of your heavy machinery or prefer to do it in-house, there are some essential pre-season maintenance tasks that you should perform. These tasks are extremely vital, as they can protect your business from unexpected downtime, repair bills, and employee injuries. Winter Prep Checklist With the joys of the Winter holidays comes the reality of harsher outdoor conditions. Battery. Inspection Basics: How to Spot a Faulty Used Forklift. Do you want a rough terrain vehicle for outdoor use or one that has non-marking rubber tires for your warehouse?

While all of these things are important to think about before buying, perhaps one of the biggest factors to consider is whether to buy a new or used forklift. Both new and used forklifts come with their own set of pros and cons, but used forklifts tend to be more cost-effective from the get-go (as long as the machine is in good condition). Read on as we discuss what to look for when inspecting a used forklift so that you don’t get stuck with a faulty lift truck. Forks & Mast You should begin by checking the vehicle’s forks for any cracks, bends, or other types of distortion. Mast Rails, Lift Chains, & Cylinders When inspecting the mast rails, be sure to look any welds or cracks that could compromise the integrity of the machine.

Things to Consider When Buying a High Lift Pallet Jack. The versatility of a pallet jack is seen in its various applications; these material-handling machines are commonly found in several settings, including grocery stores, behind-the-scenes retail environments, industrial warehouses, and more. Their popularity can be attributed to the fact that they make it easier to move goods from storage to their next destination, as they lessen the physical strain that employees would have to endure without the help of a pallet jack. Keep reading as we explore the four factors you should consider when purchasing a pallet jack. Price It is important to understand that you should only pay for what you need. If your business only deals with smaller loads that max out around 500 pounds, it would be silly to purchase a high lift pallet jack that boasts a ridiculously high capacity. How to Properly Clean New Forklifts. Cleaning your new forklifts is an essential (but sometimes overlooked) part of maintaining your fleet.

Taking care of your forklifts through a quick clean is an easy way to prolong the life of your machines and prevent damage. This is true for indoor and outdoor vehicles alike, as the former can collect dust and grime, while the latter is prone to getting mucky from mud and water. High Lift Pallet Jack - Manual Versus Electric. If you are in the market for a high lift pallet jack, you need to understand the different types available for purchase before you actually buy. The two types of pallet jacks include manual and electric, and both have their own pros and cons.

Because the price difference between these two types of pallet jacks is quite substantial, you will want to make sure that you evaluate all of the specs so you know which one is right for your specific application. Keep reading as we take a look at some of the features you should consider when deciding between an electric versus manual pallet jack.

Major Considerations. 3 Things to Check Before Purchasing Used Pallet Racking. Used pallet racking is incredibly cost-effective and even good for the environment, as it reduces the amount of resources and emissions required to produce a new racking unit. However, if you have plans to order secondhand shelving from an industrial equipment dealer, be sure check the condition of the racking prior to purchasing. This is mainly because used racking can create hazardous situations in your warehouse if it is in poor condition. In order to determine if the used racking is conducive to a safe working environment, it is important to look at the amount of rust on the unit, damage to any beams, and the integrity of the uprights. Leasing, Buying, or Forklift Rental: Which One is Best for Business?

Forklifts are no small investment. In fact, next to your employees, they are quite possibly your largest expense. As a warehouse manager, your job is to seek out ways to measure those costs and minimize them. With financial tools becoming more advanced and material handling equipment becoming more and more complex, it might be time to rethink the way you “buy” your lift trucks. Read on as we explore the various avenues for acquiring your vehicles, including leasing, buying, and forklift rental. The Benefits of Heavy Duty Industrial Shelving. Because products must remain in good condition while they are being stored, proper shelving is an essential part of any warehouse space. Maximize Workspace with Warehouse Storage Racks. Warehouse Equipment Rental: Some Considerations.

Hiring the Right Company: A Warehouse Equipment Rental Checklist. Maintenance Tips for Your Warehouse Floor Sweeper. Posted by darrequipment on October 8th, 2020. Types of Forklifts: From an Order Picker to a Counterbalance Forklift. The Pros and Cons of New and Used Pallet Racking. Battery Maintenance for Electric Forklifts. The Benefits of Preventative Forklift Service & Maintenance. Forklift Maintenance: Important Factors to Consider. As a warehouse manager, you probably know that any disruption to the daily workflow is a large inconvenience and could have a serious financial impact on your business. Forklift Attachments: The Most Common & Helpful Forklift Parts. Tips for Installing a Pallet Racking System.

A Guide to the High Lift Pallet Jack. Know Your Forklift Parts: Picking the Right Mast. Know Your Forklift Parts: A Guide to Forklift Terminology. Darr Receives Unicarriers Premiere Award 2019. Rodeo Recap 2020: From CAT Lift Trucks to a VIP Party. Helpful Tips When Buying Used Forklifts. Warehouse Tech Trends 2020: From Automated Warehouse Order Picker to WMS. Ways to Improve Warehouse Efficiency: From Industrial Racking Systems to Training. A Generation of New Forklifts: Automation in the Material Handling Industry. Types and Uses of Order Pickers. Five Types of Warehouse Storage Racks. Forklift Rental: The Benefits of Rough Terrain Forklifts. A Guide to Purchasing a High Lift Pallet Jack. Forklift Maintenance: Avoiding Forklift Hazards. What to Expect from Warranties for Used Forklifts. Heavy Lifting Equipment Brand Forklift and Warehouse Racking Solutions. Forklift and Heavy Industrial Shelving Equipment. The Benefits of Warehouse Automation. Industrial Warehouse Forklift Equipment Rental and Maintenance Services.

Tips for Saving Money When You Buy a Forklift. Forklift Sensors: Necessary Technology or Optional Feature? – Forklift Sales, Forklift Rental, Parts and Services. Benefits of Electric Forklifts. Space Saving Industrial Racking Systems. Benefits of Buying a Reach Truck Forklift. How And When to Replace Forklift Tires - Vehicle Maintenance and Repair. Six Reasons to Use an Electric Floor Scrubber. How to Save Money on Forklift Maintenance. Darr Equipment Co. Pallet Racking Height: Factors to Consider. Darr Equipment - Heavy Industrial Equipment and Services.

Is It Safe to Buy Used Pallet Rack Uprights?

Darr Equipment Co. Heavy Industrial Equipment Forklift and Warehouse Solutions. How an Order Picker Can Improve Warehouse Efficiency. Tips for Safely Using Heavy Duty Industrial Shelving. Cost-Effective Space Saving Solutions for Your Warehouse. Forklift Maintenance: Tips for Cleaning Your Machine. New Equipment Cushman Speciality Utility Vehicles. Taylor Dunn Specialty / Utility Vehicles.

Buying a Forklift in 2019? Here Are 7 Ways to Plan. Darr Equipment Co., United States, Texas, Dallas. Build Your Career With Forklift Service Companies in Dallas. Forklift Parts in Dallas. Preserve Your Electric Forklifts with These Storage Tips. Pricing Insights for the Next Time You Buy a Forklift. Autocar Terminal Tractor. Electric Forklift Maintenance Basics.

Ottawa Terminal Tractor. Misconceptions About Used Forklifts – Forklift Sales, Forklift Rental, Parts and Services. Darr Equipment Co. Types of Warehouse Racking Systems. Money-Saving Advantages of Equipment Rental. Factory Cat Scrubbers & Sweepers. DARR Equipment. DARR Equipment Profile. Should You Buy Used Pallet Racking? – Forklift Sales, Forklift Rental, Parts and Services. How to Gauge the Lifespan of a Used Forklift. Darr Equipment Co. - Fork Lift Trucks. Advance Scrubbers & Sweepers. Darrequipment.com. Liftking Forklifts. How to Choose a Pallet Racking System. US Business Directory. Darr Equipment - Dallas, TX 75220 - (800)964-5438. Darr Equipment. Hubtex Forklifts. Why Buy Local Forklift Parts from Dallas – Forklift Sales, Forklift Rental, Parts and Services. Darr Equipment at 2626 Willowbrook Road, Dallas, TX on Fave. Sellick Forklifts. Darr Equipment Client Reviews and Ratings.

Princeton Forklifts. Kalmar Forklifts.