Professional 3D printing made accessible. The Vertical Axis Wind Turbine (VAWT) model was launched alongside the Ultimaker 2+ models.

A simple model with great implications. On the surface, it’s an aesthetically pleasing demo piece. But deeper, we have a concept that is wonderfully empowering. Imagine If we could create a turbine that is open source, inexpensive and easily reproducible anywhere in the world via desktop 3D printers. We would be able to make small scale renewable energy production instantly available with no requirement of a distribution center. Without a 90 degree corner in sight, this model exemplifies the ease in which 3D printing is able to create complex precise curved shapes that function in an assembly. 3D Design Philosophy The turbine is intended to be printed fully hollow so it can be as light as possible while maintaining the cleanest external surface.

What you'll need. Axial Flux Lesson #1 - Mike's Windmill Shop. Winding a three phase axial flux stator the Mike’s Windmill Shop way.

How I built an electricity producing wind turbine. Several years ago I bought some remote property in Arizona.

I am an astronomer and wanted a place to practice my hobby far away from the sky-wrecking light pollution found near cities of any real size. I found a great piece of property. The problem is, it's so remote that there is no electric service available. That's not really a problem. VAWT. Yet another VAWT.....

The "Lenz Turbine" I've always had sort of a soft spot for the Vertical Axis Wind Turbines because of the advantages they offer. Unfortunately, most of them such as the Savonius aren't very efficient but do offer low wind characteristics. About a year ago I was emailed a patent of a VAWT that was a bit different. This one used the "Venturi effect" to duct air around the wings. I started playing around with small units and built a coffee can model which ended up running at 700 rpm and was named the "700 RPM Coffee can". Basically I divided it up into 4 sections, cut two out and taped them back into the can on the two remaining sections. I decided to build a larger one using a plastic 5 gal bucket and similar techniques were used in the construction. After trying a bunch of different drums and shapes I decided to get a bit more scientific in my testing instead of my hit 'n miss style up to this point. Lenz v2 ... update 8/28/05. DIY PC Fan Wind Generator Plans, Upcycle a Fan.

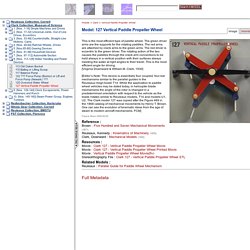

Hugh Piggott's blog. Hugh Piggott's blog. How to use a charge controller. BladeDesign.pdf. KMODDL - Kinematic Models for Design Digital Library. This is the most efficient type of paddle wheel.

The green driver arms are the supports for the rotating paddles. The red arms are attached by crank arms to the green arms. The red driver is eccentric to the green driver. The rotating action of the two causes the paddles through the crank arm connections to be held always in a vertical position with their surfaces always meeting the water at right angles to their travel. This is the most efficient angle for driving. [Editor’s Note: This device is essentially four coupled, four-bar mechanisms similar to the parallel guides in the Reuleaux-Voigt model T14. Introduction_darrieus_wind_turbines.pdf. Aerodynamic references for small wind turbines. © Martin Gregorie, 2002 Introduction This paper arose from a seminar at the 2002 ITDG Associates Open Day on low cost energy sources for isolated villages.

The presentation made the case that the use of small 200-300 watt wind turbines, providing power via battery banks for high efficiency lighting, radio and TV reception was cost effective in isolated communities located in areas with suitable wind speeds throughout the year. The turbines are two or three blade machines in the 2-3 metre diameter range. This size of machine is affordable, easy to transport via pack animal or bicycle trailer and easy to install on a light-weight wire braced mast. After the seminar I was able to examine an example machine. About the author I have been a competitive model flyer, constructor and designer for 30 years.

Full size aviation has moved on to the regime of the very large and the very fast. The approach to turbine optimisation Pitch distribution Professor Eugene E. References Larrabee, E.E. Where: Small & Vertical Wind. REUK.co.uk Wind Articles Index - Page 1. DIY 2kW Wind Turbine. Electricity with Stepper Motors. Find out the basics of generating electricity with stepper motors home > wind It is not necessary to build your own complex and expensive alternator for a small DIY wind turbine - small stepper motors can be perfect for the job.

Found in old computer printers (dot matrix, daisy wheel, and some laser), stepper motors are cheaply (if not freely) available and generate AC power at low rates of rotation (far lower than similarly sized DC motors for example). Therefore small wind turbine blades can be mounted directly onto the motor shaft rather than through a noisy and complicated gearing mechanism. PVC Wind Turbine Blades. Learn how to make your own PVC wind turbine blades home > wind | educationPVC Wind Turbine Blades are becoming more and more common for homemade domestic wind turbines.

The raw material, PVC pipe, is easy to find, relatively cheap, easy to work with, and performance is more than acceptable for a small basic wind turbine generator. PVC wind turbine blades can simply be bolted onto a Permanent Magnet Alternator or suitable Stepper Motor and you already have a basic wind turbine.One of the most difficult parts of making your own wind turbine is producing suitable blades. Wind turbine blades go through enormous stresses and must be made to quite tight tolerances if they are to balance and not send destructive vibrations through your wind turbine.Typically blades are carved from wood, but this is very time consuming, difficult, and requires a wide range of tools (saws, drills, sanders, clamps, work bench etc). (Click here to find out more about Making Wooden Wind Turbine Blades).