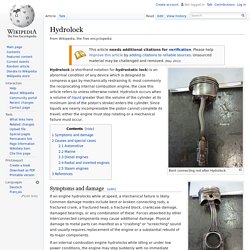

Hydrolock. Bent connecting rod after Hydrolock Same connecting rod, turned 90° Hydrolock (a shorthand notation for hydrostatic lock) is an abnormal condition of any device which is designed to compress a gas by mechanically restraining it; most commonly the reciprocating internal combustion engine, the case this article refers to unless otherwise noted.

Hydrolock occurs when a volume of liquid greater than the volume of the cylinder at its minimum (end of the piston's stroke) enters the cylinder. Since liquids are nearly incompressible the piston cannot complete its travel; either the engine must stop rotating or a mechanical failure must occur. Symptoms and damage[edit] If an engine hydrolocks while at speed, a mechanical failure is likely. If an internal combustion engine hydrolocks while idling or under low power conditions, the engine may stop suddenly with no immediate damage. Amounts of water significant enough to cause hydrolock tend to upset the air/fuel mixture in gasoline engines. Drain Cocks_1. Working Oscillating Steam Engine MKI by cbabbage. Model Steam Engine Plans.

Wobblers, otherwise known as oscillating steam engines are the simplest of all model steam engines to produce for the novice model engineer considering having a lack of the necessary machine tools available to anyone new to this hobby.

They come in many configurations but mostly there are two types and these are covered in our offerings of free wobbler steam engine plans. Those that have an inlet and exhaust passing through the same portway, or those where the inlet is at or near the top of the cylinder, with slots near the bottom of the cylinder to allow the spent steam to vent to atmosphere, that way making the construction easier to accomplish. The second is mainly used with single acting steam engines where the power stroke is from one direction only as double acting steam engines would need the combined inlet and outlet at each end of the cylinder or a longer cylinder and piston assembly and a complicated crank arrangement. Free plans. 060%20%20%20%20%20%20%20%20%20%20%20%20%20%20%20%20Twin%20cyl%20osc%20BoatEngine%20-%20first%20timers.pdf.

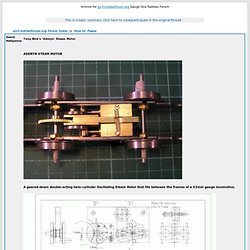

MV%20deo%2010x20.pdf. Diyoscillator. Moteur a vapeur oscillant. Double Acting Twin Oscillating Engine - Mamod Model Steam Engine and Train Products and Accessories. Vapeur modele reduit. Tony Bird's 'Aderyn' Steam Motor. .Cylinder Blocks Drawing The finished cylinder block is 22.5mm long and 11mm x 9.5mm section, and is bored offset ¼” 21.5mm deep. ½” square brass material was used which had to be machined on two of its sides.

Square brass at 7/16” would be better as it is 11.11mm square so would only have to be machined on one of its side. The brass was cut into 25mm length blanks, cleaned up of any burrs and stuck on to a wax chuck using shellac. Machined to 11mm thick removed turned 90 degrees and replaced on chuck and machined to 9.5mm. Fit the wax chuck into a 3 jaw chuck. Two or four of the blanks are held together with masking tape to machine their ends in a 4 jaw chuck. The cylinder bore was drilled using a 6.3mm drill which is a little less than the ¼” diameter of the finished bore. The tools used: Two new 6.3mm drills. A milling machine was set up to allow for the offset of the bore using the edge of a machine vice as a reference point. The bored cylinders were marked out for the five 1.6mm holes. Steam Engine #8 - PM Research Inc. Model Engines. Hielscher Mini Steam Engine "Andreas"-010130. Nanus -Einzelteile.