30kw Brushless Outrunner Motors 120v 500a Esc For Electric Drone - Buy Powerful Electric Motors For Electric Mega Drone,Mega Motor For Mega Drone,Motors And Esc For Electric Drone Product on Alibaba.com. 15470 30KW bldc outrunner motors with 120v 500A esc for mega drone Specifications MAX AMP: 400AESC:400/450AMAX VOLT: 120VRESISTANCE (mOhm): .94 Thrust: 70-75Kg SIZE: 154 x 69.5( without shaft )Stator: 135*35mmWEIGHT (kg):3.4kgSHAFT: 15mm Accessory pack: Yes Package: 15470 1pcs 120v 500A esc 1pcs Exclude the 36inch propeller, if you need, we can provide separatively Factory photos: Our company introduction: Dongguan Freerchobby Co., was established in 2011.

Untitled. Untitled. When you first sit in the cockpit of an electric-powered airplane, you see nothing out of the ordinary.

However, touch the Start button and it strikes you immediately: an eerie silence. There is no roar, no engine vibration, just the hum of electricity and the soft whoosh of the propeller. You can converse easily with the person in the next seat, without headphones. The silence is a boon to both those in the cockpit and those on the ground below. Aixro XF40 Rotary Wankel Multi-Purpose Aero Engine – Aixro Rotary Engines – Aircraft, Karting, Paragliding & Development. LIquidPiston Unveils Tiny But Powerful Rotary Engine. A new kind of engine has showed its stuff for the first time outside the lab, and though it merely made a go-kart go, it could well be the start of something big.

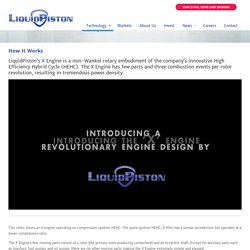

The engine is a rotary design, a pistonless setup that maximizes the power-to-weight ratio. It’s the fruit of a dozen-odd years of work by LiquidPiston, a startup co-founded by Alec Shkolnik, who has a Ph.D. in computer science, with a specialization in AI and modeling. The engine itself is based on combustion technology developed by his father, Nikolay, a Soviet-trained mechanical engineer who retrained in the United States as a physicist. Error loading player: No playable sources found There’s no liquid, though, and no piston: The company has outgrown a name that referred to a design that used both to convert expanding gas into propulsive force.

“It’s kind of a Wankel flipped inside out, a design that solves the old problems with sealing and fuel consumption,” says company founder Alec Shkolnik. Think Your Project Can‘t Afford A BLDC Motor? Think Again! Michael Bloom, PresidentSinotech According to conventional wisdom, brushless DC (BLDC) motors offer many advantages over conventional brush motors but they’re much more expensive.

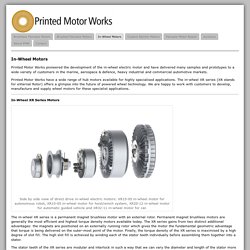

In fact, advances in BLDC design and manufacturing make brushless motors competitive with high-grade brush motors. Figure 1. Exploded view of BLDC motor. In-Wheel Motors. Printed Motor Works pioneered the development of the in-wheel electric motor and have delivered many samples and prototypes to a wide variety of customers in the marine, aerospace & defence, heavy industrial and commercial automotive markets.

Printed Motor Works have a wide range of hub motors available for highly specialised applications. The in-wheel XR series (XR stands for eXternal Rotor) offers a glimpse into the future of powered wheel technology. Homemade Brushless construction 3D printed. Brushless Motor - makeSEA. By Christoph Laimer.

Enstroj EMRAX 35, 50, 90 KW Continuous Power (limited Production), 300, 600 KW Peak Power (prototype) Updated by Bill Lofton 11/2/15 Courtesy of Enstroj Enstroj designs, develops, and manufactures the EMRAX line of electric motors for aircraft, motorcycle, automobile, and boat propulsion.

The EMRAX 207, 228, and 268 motors are in production and the EMRAX 348 motor is under development at this time. EMRAX motors power the Pipistrel Taurus Electro G2 and other aircraft flying today. Enstroj Background Please login to view this content. 3D Printed DC Motor - All. Design specifications for the brushless DC motor were established based on the principle that the motor should be easy to construct with readily available parts, and should provide qualitative performance similar to many commercially available DC motors, such as those used in small electric fans.

The motor was designed as a 3-phase, 4-pole brushless DC motor with 4 - N52 neodymium magnets on the rotor, and 3 wire wrapped solenoids connected to the stator. The brushless design was chosen because of the increased efficiency, reduced number of mechanical parts, and lower friction. The N52 magnets were chosen for their strength, price, and easy availability. Brushless motor control is discussed further in the ‘BLDC Motor Control’ section. Table 2 shows a comparison of brushless and brushed DC motors. Turnigy CA120 150kv Brushless Outrunner (100cc equiv) I am running this motor with fat boy speedy on 2x 4x 3s 5000ma turnigy lipo batteries in parallel with a 28x12 pt prop flying 3D getting about 10 minutes flight with about 50pcnt battery charge left hope to learn how to download darta next and will repost the results shortly regards john snr. this motor made by Zhuhai GS Model Accessories MFG., Ltd.

Hobbyking descriptions and product configuration table don't match the product. Hobbyking, could you fix it please to prevent confusion. I bought one already until I discover the manufacturer website. they have the bigger version, which what I want for my application. Advanced Innovative Engineering (UK) Ltd. LiquidPiston. How It Works LiquidPiston’s X Engine is a non-Wankel rotary embodiment of the company’s innovative High Efficiency Hybrid Cycle (HEHC).

The X Engine has few parts and three combustion events per rotor revolution, resulting in tremendous power density. This video shows an X engine operating on compression-ignition HEHC. The spark-ignition HEHC, X Mini, has a similar architecture but operates at a lower compression ratio. The X Engine’s few moving parts consist of a rotor (the primary work-producing component) and an eccentric shaft.