Plastic. Household items made of various types of plastic IUPAC definition Generic term used in the case of polymeric material that may contain other substances to improve performance and/or reduce costs.

Note 1: The use of this term instead of polymer is a source of confusion and thus is not recommended. Note 2: This term is used in polymer engineering for materials often compounded that can be processed by flow.[2] Composition Most plastics contain organic polymers. Additives Classification Plastics are usually classified by their chemical structure of the polymer's backbone and side chains. Thermoplastics and thermosetting polymers There are two types of plastics: thermoplastics and thermosetting polymers. Thermosets can melt and take shape once; after they have solidified, they stay solid. Other classifications Other classifications are based on qualities that are relevant for manufacturing or product design. Biodegradability Natural vs synthetic Most plastics are produced from petrochemicals.

History. Dilatant. A dilatant (also termed shear thickening) material is one in which viscosity increases with the rate of shear strain.

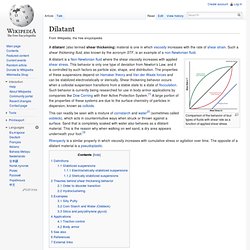

Such a shear thickening fluid, also known by the acronym STF, is an example of a non-Newtonian fluid. Comparison of the behavior of four types of fluids with shear rate as a function of applied shear stress A dilatant is a Non-Newtonian fluid where the shear viscosity increases with applied shear stress. This behavior is only one type of deviation from Newton’s Law, and it is controlled by such factors as particle size, shape, and distribution. The properties of these suspensions depend on Hamaker theory and Van der Waals forces and can be stabilized electrostatically or sterically.

This can readily be seen with a mixture of cornstarch and water[2] (sometimes called oobleck), which acts in counterintuitive ways when struck or thrown against a surface. Rheopecty is a similar property in which viscosity increases with cumulative stress or agitation over time. Where: Introduction to polymers. Influences of Material Properties on Energy Absorption of Composite Sandwich Panels under Blast Loads : Journal of Composites for Construction: Vol. 16, No. 4. Su, H. and McConnell, J. (2012). ”Influences of Material Properties on Energy Absorption of Composite Sandwich Panels under Blast Loads.”

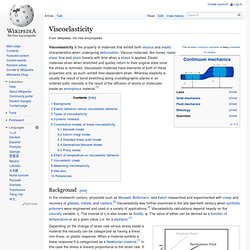

J. Compos. Constr., 16(4), 464–476. Technical Papers Submitted: 27 January 2011 Accepted: 17 November 2011 Published: 19 November 2011 ISSN (print): ISSN (online): 1943-5614 American Society of Civil Engineers CODEN: jccof2 1Graduate Research Assistant, Dept. of Civil & Environmental Engineering, Univ. of Delaware, Newark, DE, 19716. 2Assistant Professor, Dept. of Civil & Environmental Engineering, Univ. of Delaware, Newark, DE, 19716 (corresponding author). This paper presents a study on the influence of material properties on the energy absorption capabilities of composite sandwich panels. Viscoelasticity. Background[edit] Different types of responses ( ) to a change in strain rate (d /dt) Depending on the change of strain rate versus stress inside a material the viscosity can be categorized as having a linear, non-linear, or plastic response.

When a material exhibits a linear response it is categorized as a Newtonian material.[1] In this case the stress is linearly proportional to the strain rate. Some phenomena in viscoelastic materials are: if the stress is held constant, the strain increases with time (creep);if the strain is held constant, the stress decreases with time (relaxation);the effective stiffness depends on the rate of application of the load;if cyclic loading is applied, hysteresis (a phase lag) occurs, leading to a dissipation of mechanical energy;acoustic waves experience attenuation;rebound of an object following an impact is less than 100%;during rolling, frictional resistance occurs. a) Applied strain and b) induced stress as functions of time for a viscoelastic material. Mechanical Behavior of Materials - Marc André Meyers, Krishan Kumar Chawla.

Www.ciar.org/~ttk/mbt/papers/ijie01/ijie_25_455.pdf. Www.arpapress.com/Volumes/Vol7Issue1/IJRRAS_7_1_01.pdf. Www.mate.tue.nl/mate/pdfs/10702_sec.pdf.