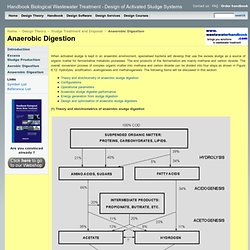

Horno 3 Steel Museum / Grimshaw. Handbook Biological Wastewater Treatment - Design Theory - 8.3 Anaerobic Digestion. When activated sludge is kept in an anaerobic environment, specialised bacteria will develop that use the excess sludge as a source of organic matter for fermentative metabolic processes.

The end products of the fermentation are mainly methane and carbon dioxide. The overall conversion process of complex organic matter into methane and carbon dioxide can be divided into four steps as shown in Figure 8.12: hydrolysis, acidification, acetogenesis and methanogenesis. The following items will be discussed in this section: (1) Theory and stoichiometrics of anaerobic sludge digestion The four metabolic steps (hydrolysis, acidogenenis, acetogenenis and methanogenesis) as shown in Figure 8.12 will be discussed in more detail, including the stoichiometry of the different reactions and the effect on alkalinity and pH.

Advanced anaerobic digestion: More gas from sewage sludge. Advanced Anaerobic Digestion: More Gas from Sewage Sludge.

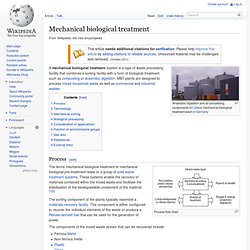

BIOFUEL. Dirty_truths. Mechanical biological treatment. Anaerobic digestion and air processing components of Lübeck mechanical biological treatment plant in Germany A mechanical biological treatment system is a type of waste processing facility that combines a sorting facility with a form of biological treatment such as composting or anaerobic digestion.

MBT plants are designed to process mixed household waste as well as commercial and industrial wastes. Process[edit] Process flow chart The terms mechanical biological treatment or mechanical biological pre-treatment relate to a group of solid waste treatment systems. The sorting component of the plants typically resemble a materials recovery facility.

The components of the mixed waste stream that can be recovered include: Terminology[edit] MBT is also sometimes termed BMT – biological mechanical treatment – however this simply refers to the order of processing, i.e. the biological phase of the system precedes the mechanical sorting. Torrefaction. Torrefaction removes moisture and volatiles from biomass, leaving bio-coal.

Torrefaction of biomass, e.g. wood, can be described as a mild form of pyrolysis at temperatures typically ranging between 200 and 320 °C. During torrefaction, the biomass properties are changed to obtain a much better fuel quality for combustion and gasification applications. Torrefaction leads to a dry product with no biological activity like rotting. Torrefaction combined with densification leads to a very energy-dense fuel carrier of 20 to 25 GJ/ton lower heating value (LHV).[1] Torrefaction makes the material undergo Maillard reactions. Biomass can sometimes be an important energy source.[2] However, nature provides a large diversity of biomass with varying characteristics. Process[edit] Torrefaction is a thermochemical treatment of biomass at 200 to 320 °C.

During the process, the biomass typically loses 20% of its mass (dry bone basis) and 10% of its heating value, with no appreciable change in volume. Energy-fuels-mg18725151500. Humanure: the end of sewage as we know it? Laura Allen, a 33-year-old teacher from Oakland, California, has a famous toilet.

To be honest, it's actually a box, covered in decorative ceramic tiles, sitting on the cement floor of her bathroom like a throne. No pipes lead to or from it; instead, a bucket full of shavings from a local wood shop rests on the box next to the seat with a note instructing users to add a scoopful after making their "deposit. " Essentially an indoor outhouse, it's a composting toilet, a sewerless system that Allen uses to collect her household's excrement and transform it into a rich brown material known to fans as "humanure. " Allen is a founding member of an activist group devoted to the end of sewage as we know it. Her toilet recently made an appearance in the Los Angeles Times—which might explain why she didn't seem surprised when I emailed her out of the blue to ask if I could use it. To most Americans, Allen's system would seem eccentric, if not downright weird.

"Look," he said. Inhabitat - Green Design Will Save the World » Architecture.

T?F. 2011_02_02_the_energy_report_full. Recycling animal and human dung is the key to sustainable farming. © Illustrations in red & black: Diego Marmolejo for low-tech magazine.

The innocent looking water closet breaks up a natural cycle in our food supply. Basically, it turns extremely valuable resources into waste products. When we grow crops, we withdraw essential nutrients from the soil: potassium, nitrogen and phosphate, to name but the most important. During the greater part of human history, we recycled these nutrients through our bodies and returned them to the soil, via excreta, food trimmings and the burial of dead. Today, we flush them mostly into the sea (see the infographic below, source). This is problematic and unsustainable, for three main reasons. Secondly, we need artificial fertilizers to keep our soil fertile. Water closets are energy-intensive Fresh water production, the construction and maintenance of sewers, the treatment of sewage (and sewage sludge), and the production of inorganic fertilizers are all energy-intensive processes.