Focus matériaux : le TPU-92A OWA. Sbase/Smoothieware - Use a Free PWM Pin and Power Expander or SSR to Control Fans.: 3 Steps (with Pictures) PWM pins on Sbase delivers 3.3v or so and is considered + in regards to wiring.

Note: I recommend using wires easily recognizeable when doing electrical and electornical things. Like red for power/+/vin and black for -/gnd. Manual - Overview. This manual was sponsored by and written by Gary Hodgson Slic3r is a tool which translates digital 3D models into instructions that are understood by a 3D printer.

It slices the model into horizontal layers and generates suitable paths to fill them. Slic3r is already bundled with the many of the most well-known host software packages: Pronterface, Repetier-Host, ReplicatorG, and can be used as a standalone program. This manual will provide guidance on how to install, configure and utilise Slic3r in order to produce excellent prints. RepRap printDoctor — Wiki LOGre. Ressources:repetier-host_slic3r [Wiki du HATLAB] Z probing with Smoothie. Last weekend I finally decided to implement a Z probe on my Mendel90.

I frequently swap the mirror I use as a print surface, and I think the wooden frame of the M90 expands and contracts a small amount as well – whatever the reason, my Z height does fluctuate slightly and this was my primary motivation, automatically setting the bed plane was a secondary (though welcome) benefit. This was supposed to be a quick and dirty implementation, then I could get back to the new printer design – as ever, the reality turned out to be more involved. I had a couple of 9g servos laying around, and mechanical end-switches, so a servo controlled arm seemed the obvious solution. I’m not an OpenSCAD expert, so modifying NopHeads original file was out of the question in the time I had available. Just add a servo and switch. Help With BLTouch and smoothieware - Smoothie Project.

I have the probe working perfectly without a Z Endstop on my Cartesian Printer using Delta Grid Auto Levelling.

I have Wiring Configured similar to the most recent diagram from BLTouch but i DO NOT have a resistor wired in and it works perfectly. Mine is wired as: Probe Z Min Signal & Ground - Z Min Endstop Signal & Ground on the board. Probe 5 Volt Supply - Z Min Endstop 5 Volt Supply on the board. Antclabs. Sans titre. BLTouch Support - Smoothie Project. Hi I am using the following connections for my BLT, everything works, APART from when I go to print the head sits around 15mm above the bed, it's most likely something very simple BUT I can't find it out.

I also post my config in full. Plus.google. Image-to-bin. This tool generates a .bin file from any image.

Output bin contains raw image data as BGR (blue, green, red) or ABGR (alpha + BGR). Read the 3DS homebrew tutorial to learn how to use these BIN files in your homebrews. The 3DS screens are rotated -90 degrees. To fix that, the tool rotates your image +90 degrees. 1) Choose an image file: (.bmp, .png, .jpg or .gif) 2) Check your options: rotate 90° - preserve transparency 3) Download your BIN file. 3D Printing Troubleshooting: 34 Common 3D Printing Problems. Free Software Image2LCD. Taxonomy of Z axis artifacts in extrusion-based 3d printing. FTMQ6UNIN63CZON.jpg (JPEG Image, 1920 × 1440 pixels) - Scaled (53%) Doubling-stepper-motor-drivers. Probably the machine for which Smoothie is most used, due to Smoothie's roots in the RepRap project, 3D printers are fairly simple to Smoothiefy.

This is a step-by-step guide to connecting your board to the various components of the 3D printer, configuring everything, from the beginning to actual printing. This guide is a community effort, and this page is a Wiki. Please don't hesitate to edit it to fix mistakes and add information, any help is very welcome. New MKS SBASE Smoothieware-compatible board from China. I love clones when done right.

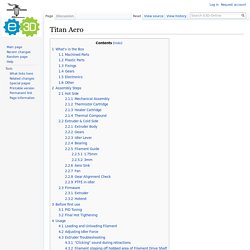

Hell, if it wasn't for clones I wouldn't be on this PC now because back in the day IBM sued over clones (hurt their business) and had they won we would not have what we have today or all would be stuck on an Apple (or rich as hell and have a real IBM). My i3 Rework is a turd. I spent thousands and thousands of hours tweaking it and it finally gave me the finger and will not lay down a first layer. 9ab5951c-724c-464d-a991-c3540cf4c361.jpg (JPEG Image, 350 × 350 pixels) Titan Aero - E3D-Online. Machined Parts Titan Aero Heatsink (1.75mm or 2.85mm) V6 Heatbreak (1.75mm or 2.85mm) V6 Heater Block V6 0.4mmm Nozzle (1.75mm or 2.85mm) Plastic Parts Titan Body (prefitted with bearing and threaded insert) Idler Lever (prefitted with bearing) 1.75mm Filament Guide 2.85mm Filament Guide.

Amazon. Insert à frapper M3 Pour le plastique sachet 20pcs SIMAF. MKS TFT 2.8" or 3.2" Touch Screen user guide. Introduction: MKS-TFT28 and MKS-TFT32 color display Touch screen is designed to control RepRap Open source 3D printer.

It can work with MKS Base, MKS GEN and MKS MINI series 3D control board. Notice: 1) Pls check the MKS Base V1.4/V1.5 or Gen V1.4 3D printer board Marlin firmware installation guide. MKS SBase 3D printer control board user guide. 1 Overview MKS SBase advantage over 2560 control board: 2. Connection Graph 3.Prerequisite for running 1)Download firemware from : Rôle et réglage des pilotes moteurs pas à pas - L'impression 3D pour tous. *** CONSEILS POUR DEBUTANTS *** (Page 1) — Section Francophone. The Toranado Precision Geared 1.75mm Extruder - Side Mount Version by Toranado3D. The Toranado Precision Geared 1.75mm Extruder - Side Mount Version - Coming January/February 2017! Introducing a new addition to the Toranado Extruder Family - The Toranado Side Mount Version!

This extruder contains all of the functionality from the original Toranado in a new form-factor that includes the following features: Toranado Precision Geared Extruder - Legacy Versions by Toranado3D. This page supports all legacy versions of the Toranado Precision Geared Extruder. - These versions are no longer officially supported, but all of the info to build one is still made available. v2.1 - Toranado Precision Geared Extruder Latest Build The Toranado Precision Geared 1.75mm Extruder - Current Build v2.02 Why the Toranado? Configurer le firmware Marlin. v6 HotEnd Full Kit - 1.75mm Universal (Direct) (12v) From mid-June 2016 E3D Hotends will transition to using a standard cartridge-type format for temperature sensors.

This means a new heater-block and thermistor cartridge will be supplied with the E3D-v6 as standard. For a full explanation read the sensor documentation page. The E3D-v6 has been redesigned from the ground up. E3D v6 Information, Installation Guides, and Review. Sharebot NG dual extruder / Kiwi fan duct with adjustable support by Camaleonte. Semaker 3D market. By Toranado3D, published V1.1 Printing @ 85mm/sec and 500mm/s^2 default acceleration Hardware Kits - v1.1 Tornado Kits. Toranado PGE X-Carriage - Prusa i3 8mm by Toranado3D. [TUTO] Step by Step autour des moteurs Pas à Pas /// Part #1 - Tutoriels - Forum pour les imprimantes 3D et l'impression 3D. Imprimantes 3d : Smartfriendz - SmartfriendzShop. RepRap Options/fr. Montage-Logresse_-_V2. Prusa P3-Steel — Wiki LOGre. Instructables - DIY How To Make Instructions. Makerarm. What is a Bowden extruder? File:P3Steel Render.jpg. P3Steel. Chroniques d'une imprimante 3D - ekito people ekito people.