Power station. History[edit] The world's first power station was designed and built by Lord Armstrong at Cragside, England in 1868.

Water from one of the lakes was used to power Siemens dynamos. The electricity supplied power to lights, heating, produced hot water, ran an elevator as well as labour-saving devices and farm buildings.[4][5] In September 1882 in New York, the Pearl Street Station was established by Edison to provide electric lighting in the lower Manhattan Island area. The station ran until destroyed by fire in 1890. Throughout the first few decades of the 20th century central stations became larger, using higher steam pressures to provide greater efficiency, and relying on interconnections of multiple generating stations to improve reliability and cost. Cogeneración de Energía. Rankine cycle. The Rankine cycle is a model that is used to predict the performance of steam engines.

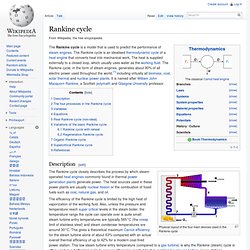

The Rankine cycle is an idealised thermodynamic cycle of a heat engine that converts heat into mechanical work. The heat is supplied externally to a closed loop, which usually uses water as the working fluid. The Rankine cycle, in the form of steam engines, generates about 90% of all electric power used throughout the world,[1] including virtually all biomass, coal, solar thermal and nuclear power plants. It is named after William John Macquorn Rankine, a Scottish polymath and Glasgow University professor. Description[edit] Physical layout of the four main devices used in the Rankine cycle. Organic Rankine cycle. The Organic Rankine cycle (ORC) is named for its use of an organic, high molecular mass fluid with a liquid-vapor phase change, or boiling point, occurring at a lower temperature than the water-steam phase change.

The fluid allows Rankine cycle heat recovery from lower temperature sources such as biomass combustion, industrial waste heat, geothermal heat, solar ponds etc. The low-temperature heat is converted into useful work, that can itself be converted into electricity. A prototype was first developed and exhibited in 1961 by solar engineers Harry Zvi Tabor and Lucien Bronicki. Working principle of the ORC[edit] Waste heat. Instead of being “wasted” by release into the ambient environment, sometimes waste heat (or cold) can be utilized by another process, or a portion of heat that would otherwise be wasted can be reused in the same process if make-up heat is added to the system (as with heat recovery ventilation in a building).

Thermal energy storage, which includes technologies both for short- and long-term retention of heat or cold, can create or improve the utility of waste heat (or cold). One example is waste heat from air conditioning machinery stored in a buffer tank to aid in night time heating. Another is seasonal thermal energy storage (STES) at a foundry in Sweden. On a biological scale, all organisms reject waste heat as part of their metabolic processes, and will die if the ambient temperature is too high to allow this. Anthropogenic waste heat is thought by some to contribute to the urban heat island effect. Biomass. Sugarcane plantation in Brazil (State of São Paulo).

Cane is used for biomass energy. A cogeneration plant in Metz, France. The station uses waste wood biomass as an energy source, and provides electricity and heat for 30,000 dwellings. Applied Thermal Engineering - An examination of regenerative organic Rankine cycles using dry fluids. Abstract This paper presents an analysis of regenerative organic Rankine cycles “ORC” using dry organic fluids, to convert waste energy to power from low-grade heat sources.

The dry organic working fluids selected for this investigation are R113, R245ca, R123, and isobutane, with boiling points ranging from −12 °C to 48 °C. Regenerative ORC is analyzed and compared with the basic ORC in order to determine the configuration that presents the best thermal efficiency with minimum irreversibility. The evaluation for both configurations will be performed using a combined first and second law analysis by varying certain system operating parameters at various reference temperatures and pressures.

Results from these analyses show that regenerative ORC produces higher efficiency compared with the basic ORC while also reducing the amount of waste heat required to produce the same power with a lower irreversibility. Performance of a small-scale regenerative Rankine power cycle employing a scroll expander. A small scroll expander has been incorporated into a power cycle for performance evaluation.

Using heat from a circulating hot oil supply, a working fluid (R123) was vapourized under pressure and fed to the inlet of the expander. Power generated was measured by a torque/rotation rate sensor as the power was delivered to a compressor. The exhausted working fluid was then sent through a regenerator to recover thermal energy, and then to an air-cooled condensation heat exchanger. To complete the cycle, the working fluid passed through a pump and was fed back to the boiler by way of the regenerator. Geothermal electricity. Geothermal electricity is electricity generated from geothermal energy.

Technologies in use include dry steam power plants, flash steam power plants and binary cycle power plants. Geothermal electricity generation is currently used in 24 countries,[1] while geothermal heating is in use in 70 countries.[2] Estimates of the electricity generating potential of geothermal energy vary from 35 to 2,000 GW.[2] Current worldwide installed capacity is 10,715 megawatts (MW), with the largest capacity in the United States (3,086 MW).[3] El Salvador, Kenya, the Philippines, Iceland and Costa Rica generate more than 15% of their electricity from geothermal sources. Solar thermal energy. The first three units of Solnova in the foreground, with the two towers of the PS10 and PS20 solar power stations in the background.

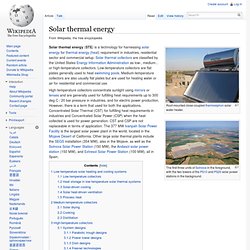

Solar thermal energy (STE) is a technology for harnessing solar energy for thermal energy (heat) requirement in industries, residential sector and commercial setup. Solar thermal collectors are classified by the United States Energy Information Administration as low-, medium-, or high-temperature collectors. Low-temperature collectors are flat plates generally used to heat swimming pools. Medium-temperature collectors are also usually flat plates but are used for heating water or air for residential and commercial use.

Low-temperature solar heating and cooling systems[edit] Nuclear power. Nuclear power, or nuclear energy, is the use of exothermic nuclear processes,[1] to generate useful heat and electricity.

The term includes nuclear fission, nuclear decay and nuclear fusion. Presently the nuclear fission of elements in the actinide series of the periodic table produce the vast majority of nuclear energy in the direct service of humankind, with nuclear decay processes, primarily in the form of geothermal energy, and radioisotope thermoelectric generators, in niche uses making up the rest. There is an ongoing debate about nuclear power.[10][11][12] Proponents, such as the World Nuclear Association, the IAEA and Environmentalists for Nuclear Energy contend that nuclear power is a safe, sustainable energy source that reduces carbon emissions.[13] Opponents, such as Greenpeace International and NIRS, contend that nuclear power poses many threats to people and the environment.[14][15][16] Use Nuclear power installed capacity and generation, 1980 to 2010 (EIA).

Plantas de Vapor. - La de la Termodinámica nos revela el principio de la conservación de laenergía, sin embargo en la realidad se sabe que esto no ocurre de forma tal, ypor lo tanto existe una restricción en cuanto a la conversión de ésta; de estaobservación se desprende la segunda ley, la cual se basa en dos afirmaciones:1. Virtual Power Plant. Bined-Cycle Gas & Steam Turbine Power Plants - Rolf Kehlhofer, Bert Rukes, Frank Hannemann, Franz Stirnimann. Ciclo de Rankine. Proceso[editar] El ciclo Rankine es un ciclo de potencia representativo del proceso termodinámico que tiene lugar en una central térmica de vapor.

Ciclos de Vapor. Ciclo Hirn - Rankine Sobrecalentado. Ciclo Rankine Recalentado. Extracción de Vapor - Regenerativo. CICLO RANKINE REGENERATIVO for termodinamica. Una bomba de calor es una máquina térmica que permite transferir energía enforma de calor de un ambiente a otro, según se requiera. Para lograr esta acciónes necesario un aporte de trabajo acorde a la segunda ley de la termodinámica (escuando una parte de un sistema cerrado interacciona con otra parte, la energíatiende a dividirse por igual, hasta que el sistema alcanza un equilibrio térmico),según la cual el calor se dirige de manera espontánea de un foco caliente a otrofrío, y no al revés, hasta que sus temperaturas se igualan.Este fenómeno de transferencia de energía calorífica se realiza principalmente por medio de un sistema de refrigeración por compresión de gases refrigerantes, cuyaparticularidad radica en una Válvula inversora de ciclo que forma parte delsistema, la cual puede invertir el sentido del flujo de refrigeración, transformando elcondensador en evaporador y viceversa.

Complemento%20sobre%20ciclos. Ciclo Rankine. Indice1. Introducción 2. Ciclo Rankine con Recalentamiento 3. Mercury vapour turbine. The mercury cycle offers an efficiency increase compared to a steam-only cycle because energy can be injected into the Rankine Cycle at higher temperature. Metallurgical developments have allowed steam-only plants to increase in efficiency over time, making the mercury vapour turbine obsolete. Mercury as a Working Fluid. The choice of mercury for a working fluid may seem bizarre- after all, it is both expensive and horribly poisonous. However, there were what appeared to be sound thermodynamic reasons for grappling with the challenges involved in its use.

Superheated Steam. If the saturated steam produced in a boiler is exposed to a surface with a higher temperature, its temperature will increase above the evaporating temperature. The steam is then described as superheated by the number of temperature degrees through which it has been heated above saturation temperature. Superheat cannot be imparted to the steam whilst it is still in the presence of water, as any additional heat simply evaporates more water. The saturated steam must be passed through an additional heat exchanger. This may be a second heat exchange stage in the boiler, or a separate superheater unit.

The primary heating medium may be either the hot flue gas from the boiler, or may be separately fired. Fig. 2.3.1Steam and force on a turbine blade. Turbinas a Vapor. Steam turbine. The rotor of a modern steam turbine used in a power plant Because the turbine generates rotary motion, it is particularly suited to be used to drive an electrical generator – about 90% of all electricity generation in the United States (1996) is by use of steam turbines.[2] The steam turbine is a form of heat engine that derives much of its improvement in thermodynamic efficiency from the use of multiple stages in the expansion of the steam, which results in a closer approach to the ideal reversible expansion process. History[edit] University of Rochester : Search. Turbinas De Vapor. 8_turbinas_de_vapor. Funcionamiento de la turbina de vapor for TESIS CARO.

Popular Mechanics. Energy Citations Database (ECD) - - Document #5358369. Steam Turbine Failure at Hinkley Point ‘A’ D. Kalderon, PhD (Eng), DIC, Dipl Ing, CEng, FIMechE, Director of Engineering* The catastrophic failure of Hinkley Point ‘A’ unit No. 5 in September 1969 was the result of spontaneous brittle fracture of a shrunk-on ***l.p. turbine disc, initiated by stress-corrosion cracking in the crown of a keyway in the disc bore. Stress corrosion cracking of disc bores and keyways was also found on a number of other discs.

The discs were made of 3 Cr-Mo steel and complied with normal acceptance standards, but due to temper embrittlement, their fracture toughness was low, and cracks only about 1/16 in deep in the concentrated stress field at the keyway crown were large enough to initiate brittle fracture. Investigation of the cause of the stress-corrosion cracking is being separately reported. Patent US3561216 - THERMAL STRESS CONTROLLED LOADING OF STEAM TURBINE-GENERATORS - Google Patents. Feb. 9, 1971 .1. H. MQORE. Eje de turbina de vapor. Para operaciones de torneado en acabado, la tecnología Wiper ha evolucionado considerablemente desde su presentación hace ya una década.