Anshuman Punj

Anshuman Punj is a post-graduate mechanical engineer and an MBA by qualification. (B.Tech.-Mechanical Engineering, M.Tech.-Tool Design, MBA-specialization in Materials Management). He has worked at various management positions in the private sector as well as a consultant Design for Tooling. (Eicher Goodearth, Modi Xerox and Hero Motors). This was followed by an illustrious career in the Indian Railways as a Class 1 officer. Coming across the upcoming and challenging field of vacuum deposition, Anshuman quit the government service in order to develop several ground breaking vacuum products that could be manufactured in-country. Today, he is the CEO of Supervac Industries, a highly successful Indian company that manufactures and supplies vacuum consumables to a large number of customers around the world. Anshuman Punj heads Supervac Industries which is known world-wide for its high quality and reasonably priced products. With 17 years of experience in the Vacuum Industry, he regularly writes articles and blogs on Vacuum products and applications.

Graphite Coating Manufacturers in India - Graphite Coating (Graphinox) Diffusion Pump Oil. Rotary Vacuum Pump Oils. Diffusion Pump Oil: How to get maximum value out of it. Diffusion pump oil equivalent of DC702 vacuum oil lubricants manufacturer supervac industries new delhi India. Silicone roots blower pump oil SV 90S pump oil vacuum oil manufacturer supplier supervac industries. High Vacuum Silicone Grease silicone grease manufacturer. Rotary Vane Vacuum Pump Oil: SV-77. Boronox: Boron Nitride Suspension. Rotary Vacuum Pump Oil SV 68 organic product information. Synthetic Rotary Vacuum Pump Oil SV 77 product information. Merry christmas 2015 supervac industries new delhi india. Vacuum Technology Simplified: Boron Nitride Powder: SV-BNP+ (Supervac Industries): Properties and FAQs.

Types of Release Agents. Manufacturers produce myriad products in a variety of shapes and sizes using molds.

These products as well as molds are made in many materials like plastic, concrete, metals, ceramic, glass etc. Molding allows the manufacturer to produce articles in the exact same dimensions and designs in the shortest possible time. While molding an article, a time comes when the composite material has to be separated (de-molded) from its mold. This is where release agents function. A release agent basically creates a slip effect between the mold article and the mold. Release agents can broadly be divided into 3 categories: Internal Release AgentsConventional or Non-Permanent Release AgentsSemi-Permanent Release Agents Internal Release Agents These are speciality release agents which are utilized by select applications only. Conventional or Non-Permanent Release Agents These are used where high slip or lubrication is a prime requirement. Happy Diwali 2015. Vacuum Diffusion Pump Oils- Supervac Industries (India) Molecular Distilled Vacuum Pump Oil: Explanation and Advantages.

Term molecular distilled vacuum oil (or MD oil) is often used in specifications of vacuum oils especially for rotary vacuum pump oils.

But very less literature is available on molecular distillation which creates confusion amongst maintenance engineers as to what exactly is Molecular distillation and how is it different from fractional distillation (which is a common way of distilling liquids). Ultra Pure Boron Nitride Powder SV-BNP PLUS. Epsom Salt- Best for Hair Care. Boron Nitride Suspension- BORONOX, Lubricant Release Agent. Boronox Plus Boron nitride suspension. Graphite Suspension – Graphinox, Lubricant Release Agent. Beware! Trap Ahead. Bhartendu Mehta (Name Changed) stormed into my chamber this morning.

He seemed to be furious. Without exchanging any pleasantries he started, “How can my machinery manufacturer loot me?” He demanded to know. I was surprised for a minute. After all, besides being a good friend, Bhartendu was a polished businessman; a stalwart in metallizing line and a thorough gentleman in his behavior. What happened Bharat? Now he sat down, took a long breath and started-“I bought a metallizing machine from a famous European manufacturer which costed a bomb. I could not help but nod in agreement. Bharat continued, “These brands are like cadavers being carried on four shoulders of the machinery manufacturer. Now I spoke- “Yes Bharat. “Absolutely”, Bharat said, “Look, you and I are both engineers. I told him, “I can understand your anguish. Bharat again started, “I am told half of the money received by these unknown oil brands is being passed on to the machinery manufacturer for ‘Endorsement’ “.

Roots Blower Booster Vacuum Pump Oil SV-90H. Vacuum Technology Simplified: Boiling Temperature of Diffusion Pump Oil Explained. High Vacuum Silicone Diffusion Pump Oil SV SIGMA. Vacuum Gauges Explained. In any vacuum system it is most important to know accurately the level of vacuum on real time basis as even a minor change in vacuum can result in process parameters going haywire and product quality getting adversely affected.

In modern day vacuum systems we use sophisticated vacuum gauges to know the vacuum accurately. In this blog post various kinds of vacuum gauges have been described. Limitations and advantages of these gauges have also been brought out so that engineers using vacuum can select appropriate gauge for the application. Ceramic Evaporation Boats. Graphite Foil For Vacuum Applications. Graphite Suspension/ Paint (Water based) : Graphinox. Roots Blower Booster Vacuum Pump Oil. Roots Blower Booster Pumps Roots Blower Booster Pump: These pumps work on the principle of positive displacement of gas.

The Roots pump consists of two impellers called roots in the shape of figure 8. These impellers are mounted on parallel shafts in a single cylinder having inlet and outlet openings on the sides. The impellers, through synchronized rotative timing, are maintained in a relative position to each other and rotated in opposite directions without any internal contact and at a very high speed measuring a couple thousand or more rpm.

The following diagram shows how the rotation of impellers traps and pushes the gas/air out. Choose the Right Type of Lubricant. How to Reduce Vacuum Time. Introduction In today’s competitive scenario a lot of stress is laid on increasing productivity by using machine time effectively.

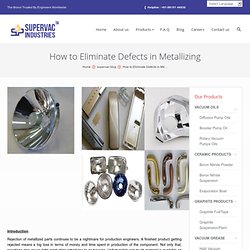

In case of Vacuum coating, process time is difficult to reduce without compromising on quality (NOT acceptable). So reducing vacuum time (time required to create desired level of vacuum before starting operation) is the only option. For example- For a batch metallizer where cycle time is 30 minutes a saving of 3 minutes in vacuum time can increase productivity by as much as 10%. Production engineers therefore are always on a lookout for fine tuning the procedures to reduce vacuum time. In this blog post various steps to reduce vacuum time have been discussed. How to Eliminate Defects in Metallizing. Introduction Rejection of metallized parts continues to be a nightmare for production engineers.

A finished product getting rejected means a big loss in terms of money and time spent in production of the component. Not only that, rejections also cause tight production schedules to go haywire. Unfortunately not much material is available on the subject and thus a scientific, systematic approach to problems is rarely possible.

Engineers are forced to try hit and trial method which wastes further time and energy or rely on advice from seniors but that can work only if the seniors have themselves faced that particular problem in the past. Defects while Metallizing, their reasons and how to eliminate these defects- 1) Burned Parts: - This is one of the most common problems in metallizing. Vacuum Technology Simplified: Why is Cleaning of Vacuum Chamber Required? High Vacuum Grease(Silicone) SV-G9 by Supervac Industries, India - Google Präsentationen. Critical Importance of Low-cost Consumables in Vacuum Processes. Various industries employ myriad consumables for vacuum operations.

These consumables may cost anywhere from a couple of hundreds to lakhs of rupees. This gives rise to the question: Are low cost consumables lesser in importance to high cost ones? Is that the reason why they cost less? I’ll give you a case in point. Then YOU decide. On January 28, 1986,the cause of the Space Shuttle Challenger disaster was determined to be the failure of an O-ring seal ………NASA has gone through considerable transformation after the accident.

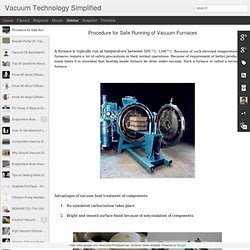

Vacuum Technology Simplified: Procedure for Safe Running of Vacuum Furnaces. A furnace is typically run at temperature between 500 o C- 1200 o C.

Because of such elevated temperatures, furnaces require a lot of safety precautions in their normal operations. Diffusion Pump Oil Product Information Supervac - Google Docs. Booster Pump Oil Top 7 Questions Answered. Q.1 What is the boiling temperature of Vapor Jet Booster Pump Oil?

Ans. Graphite Foil Top 10 Questions Answered. Q.1 Is there an alternative to graphite foil for metallizing?

Supervac Graphite Foil- SV-GF Ans. Graphite foil is highly conducting, flexible, compressible and relatively inexpensive. It serves to plug the gap between the evaporation boat and the copper clamp and so prevents any sparking that may take place. Vacuum Oil Equivalents. A lot of confusion exists in the vacuum industry. Reasons- 1. Engineers do not know which oil is equivalent to the oil supplied by their plant manufacturer. 2. Equipment manufacturers rarely give detailed specifications of vacuum oil to be used. 3. 4. Leakage Detection and Prevention in Vacuum Systems. Leaks pose biggest challenge to engineers handling vacuum systems. Leakages cripple the work and are invariably time consuming to detect. This blog post is about two major issues related to leakage – Detection and Prevention.

Leakage Detection. Silicone vacuum grease explained. What is Grease? Grease is a lubricant in a semi-solid state. It is generally applied to those machinery parts where liquid lubricants would not stay and need to be applied only occasionally. Water Resistant Sealant for Joints It also works as a sealant to keep out moisture and other unwanted materials from the system. Evaporation Boats: Top 10 Questions Answered. Q.1 What should I do if one evaporation boat fails during the cycle? Top 20 Questions About Rotary Vacuum Pumps and Oils. Synthetic rotary vacuum pump oil vs. mineral rotary vacuum pump oil. Plus.google. Supervac Industries (Supervacoils) sur Twitter. Supervac Industries - Delhi - Organisation. Suppliers of High Vaccum Pump Oils,Greases, Evaporation Boats & Suspensions. Vacuum Technology Simplified. Graphite Suspension vs. Boron Nitride Suspension.

Time and again, we are approached by users wanting to know which coating will be best for their application: graphite suspension or boron nitride suspension. Often, the same vacuum system manufacturer who earlier recommended boron nitride suspension is now recommending graphite suspension or vice versa, as a coating inside the vacuum chamber. This has led to much confusion amongst the users. In this blog, I have attempted to address this confusion by stating the properties of both along with the pros and cons of their use. Either of the two can be selected based on one’s requirement.