ProtoCycler: Free, Sustainable 3D Printer Filament - BackerKit - Pledge Manager. Flat packed go-kart, make it in hours, drives at 25mph. When you think about flat packed items you immediately think of furniture but The FlatWorks, a wooden kit company, are offering a flat packed go-kart.

The PlyFly Go-Kart can be put together within just a few hours, it runs on gas and it has a top speed of 25mph. [Image Source: Flatworks] The PlyFly Go-Kart is offered in two different types; one a 2.5 horsepower and the other a 4 horsepower. The faster of the two has a top speed of 25mph, while the smaller offers 17mph. The larger of the two can run for two and a half hours on one single tank of gas and the smaller engine runs for around an hour. Both of the engines on offer are 4 stroke clones of Honda engines that have been assembled in China and of course they meet the strict US emissions requirements.

Protótipo de impressora 3D da HP teria 1,5 metro e estaria escondida. Mediodesign Furniture by maria leon. Basic objects Mediodesign. Spring 2014. by maria leon. OpenKnit is a 3D knitter that can create garments in just one hour. Designer Gerard Rubio has created an open source robotic loom that is able to knit entire seamless garments in less than one hour (+ movie).

Springing from Rubio’s own studies with 3D printing at Escolar Superior de Disseny in Barcelona, OpenKnit allows users to design and print their own garments seamlessly on one machine. Inicio. SOLS - 3D Printed Custom Orthotics. Tisková struna Fillamentum Timberfill Light Wood Tone. Akemake. “The Future Is Here: A New Industrial Revolution” Coming to London’s Design Museum. “The Future Is Here: A New Industrial Revolution” Coming to London’s Design Museum This summer, the Design Museum in London will be offering a glimpse into the future of fabrication and manufacturing with The Future Is Here: A New Industrial Revolution, a major new exhibition about the sweeping changes in manufacturing that are transforming our world.

The exhibition, which opens July 24, is a collaboration between the Design Museum and the UK’s innovation agency, the Technology Strategy Board. Exhibition design is done by dRMM and exhibition graphics by LucienneRoberts+. Click above image to view slideshowForm Labs 3D Printer New manufacturing techniques will involve the users of products as never before, revolutionizing the role of the consumer. The boundaries between designer, maker and consumer are disappearing with a growing movement of ‘hacktivists’, who share and download digital designs online in order to customize them for new uses. Click above image to view slideshowKuka Robotics. The future is here at Design Museum / toothpicnations. Main and bottom left: The future is here exhibition designed by by Lucienne Roberts+ and drMM; Bottom right: KUKA Robotics' AGILUS robots.

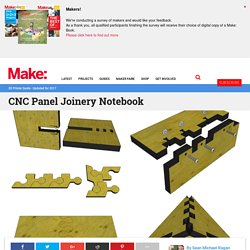

F bunk bed Rafa-Kids. CNC Panel Joinery Notebook. I’ve been collecting clever ways of slotting flat stock together since I first read Nomadic Furniture back in 1999, well before the advent of the accessible hobby-class CNC tools that today make manufacturing parts like these pretty easy.

Now, the world is full of people designing models, project enclosures, sculpture, furniture, and all kinds of other cool stuff to be assembled from parts made on laser cutters and CNC routers. I keep expecting a definitive book or website to emerge that covers the “bag of tricks” in an organized way, but so far, I haven’t found it. Maybe this article can serve as a jumping-off point. In any case, I think it’s time to share my notebook of CNC panel joinery.

In presenting this material, I want to first acknowledge my respect for the world’s established and ancient traditions of joinery. I may abuse some terms, without meaning to, and I am glad to be corrected by those who are in the know about traditional joinery. Laser vs. Biasing Cross (“X”) Joints. OpenDesk - Design for Open Making. WikiHouse. Open source work space. Made in the Future. Nervous System. Precious Plastic open-source recycling machines. Dutch Design Week 2013: Design Academy Eindhoven graduate Dave Hakkens has made his own machines for recycling plastic to make new products locally and plans to share the designs so others around the world can do the same.

The Precious Plastic machines by Dave Hakkens include a plastic shredder, extruder, injection moulder and rotation moulder, which are all based on industrial machines but modified to be less complex and more flexible. "Of all the plastic thrown away, I've heard that we recycle just ten percent and I wondered why we recycle so little," Hakkens told Dezeen at the Design Academy Eindhoven graduation show opening on Saturday. One of the issues turned out to be a lack of demand for recycled material from factories, so he visited a range of firms making plastic products to ask why they weren't using recycled plastic.

He found that difficulties with sorting plastics for recycling make the resultant material less reliable than brand new plastic. Shoe factory by Eugenia Morpurgo brings production to high streets. Italian designer Eugenia Morpurgo has set up a high-street micro factory, which uses digital manufacturing to produce her range of customisable shoes that wearers can assemble and repair themselves.

Called Don't Run - Beta, the project is a collaboration between Eugenia Morpurgo and British-Spanish designer Juan Montero to create a production line for leather shoes, so the buyer can customise their new footwear and see it being produced in-store on a laser cutter and 3D printer. Morpurgo first launched her canvas repairable shoes – that can be repaired easily because they're joined with reversible, mechanical fastenings rather then the usual stitches or glue – in 2011. Now she has followed up with a new range of colourful sandals, lace-ups and boots using the same system, but with leather uppers designed by Sophia Guggenberger, Anastasija Mase and Eliška Kuchtová.

Customers first choose the style of shoe they want and the pattern is adjusted to their size on-screen. Henk Lamp by Jos Blom. Easily deconstructed: Henk Lamp by Jos Blom announces itself as simple, two wooden pieces that slot together to form a tripod base with built-in carrying handle, and two translucent plastic shells as a diffuser, all held together by an easily removed elastic band.

(Click the images below for full sized images) Henk, Jos Blom. Futures Past: Design and the Machine, MIT. How to Make Almost AnythingThe Digital Fabrication RevolutionNeil Gershenfeld. Lean Manufacturing and Technology.