A.b.b. - amateur boat building - howto make oars. From Jim Michalak's Boat Designs I'm going to show drawings for 7' oars which are about the most useful length for me.

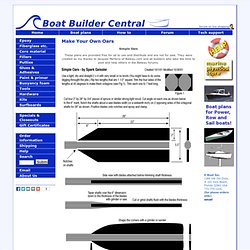

The oars I make are really derived from the patterns of the late Pete Culler. They are characterized by having heavy square looms inboard of the locks and long narrow blades in the water. An example is shown in Figure 1. The square looms are easy to build, help balance the oar, help locate the oar in the locks, and keep the oar from rolling around on the wales. The long narrow blades go against modern thinking of spoons, but for long distance rowing, long and narrow is the way to go. Oars are made from four materials - wood, glue, leathers and varnish. For wood, I use 1x6 pine boards.

For glue I prefer plastic resin "Weldwood" glue and doubt if there is anything better for making oars. For leathers I don't use leather. For varnish I use ordinary oil based spar varnish. Now let's talk tools. You can draw patterns of the outer pieces and cut them out. Here is how it's done. Boat Builder Central - Howtos. Simple Oars These plans are provided free for all to use and distribute and are not for sale.

They were created as my thanks to Jacques Mertens of Bateau.com and all builders who take the time to post and help others in the Bateau forums. Download or view this image as an AdobeAcrobat PDF. Or right-click on the image (on a PC) and save the image to your computer for printing. Some Assembly Images Oar Hardware Considerations There are 4 types of oar locks - ribbed, round, north river and clamped.

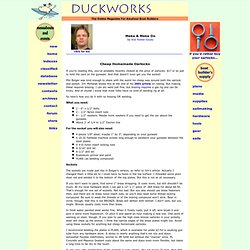

The North River type keep the oarlock in position and the oar perpendicular to the water. There are 3 basic types of oarlock sockets - edgemount, sidemount and topmount. All of these parts also usually come in stainless, bronze, brass, or zinc-coated. Some Oar Links. Wood Be Creative: A Shop Journal for Red River Canoe & Paddle. Duckworks. Sockets The sockets are made just like in Bolger’s version, so refer to Jim’s article.

Actually I changed them a little bit to I could have no holes in the top surface. I threaded some plain steel rod and welded it to the bottom of the top plates. But this is not at all necessary. If you don’t want to paint, find some 1” brass strapping. In fresh water painted steel works fine. I recommend bedding the plates in PL400, which is available for under $3 for a caulking gun tube from any hardware store. In any case, the construction of the sockets is very simple. If you don’t want to do the metalwork, there’s an alternative. Mostly. Thole Pins Of course these oarlocks are basically thole pins. Rope Bands Here’s the trick that makes this all work. Simply tie each end of the larger line to the bolt with a pair of half hitches.

I have a feeling that this “quick & dirty” method is actually much stronger than the method I originally used. Setting It Up Now this will seem backward to many of you. How to make your own oars. Oarlocks. These are "instant" oarlocks designed by Phil Bolger and "Dynamite" Payson.I made them from stainless steel rod, sheet, and wire.The string tethers keep them from sliding off the oars and getting lost.If the rubber hose is too tight or stiff to slide on, put it in hot water to soften and lubricate it.

Make the strap part of the oarlock big enough so the oar can pivot without bending or binding in the strap. Row so the oar pushes against the rod. Happy rowing! More paddle and oar making projects:Here's the quickest way I know to make a paddle.How to make an Eskimo style kayak paddle from a 2x4 in 1.5 hoursMake a steering oar for a Marshall Islands Racing canoe. Single Oar propulsion - Yuloh, Ro, Scull... Quick-N-Dirty Oars. QUICK-AND-DIRTY OARSBy David Goodchild A few years ago I built a small, pram, sailing-dinghy just for fooling around.

Last summer, I wanted to introduce my young grand-niece and grand-nephew (ages nine and six respectively) to small boat sailing. The dinghy however is just a tad under 8-feet overall, and the best oars for this boat are also 8 feet long. This of course means that they will not fit into the boat comfortably,--especially when anyone is in it. This calls out then for two-piece oars. Market but they are very pricey. I made these in just under an hour for absolutely ZIP!

The entire materials list consists of: 2 scraps of plywood about 20" by 7" 2 sections of 1 1/2" PVC plumbing pipe (usually 10' long) About 6' of 1 1/2" closet rod or dowel 18 galvanized, 1 1/4" deck (drywall) screws And that's it!